Two conductors with different components (called thermocouples wire or thermodes) are connected to form a loop. When the temperature of the junction is different, an electromotive force will be generated in the loop, this phenomenon is called the pyroelectric effect. And this electromotive force is called thermoelectric potential, which is the so-called Seebeck effect.

The Working Principle of K-Type Industrial Oven Thermocouple

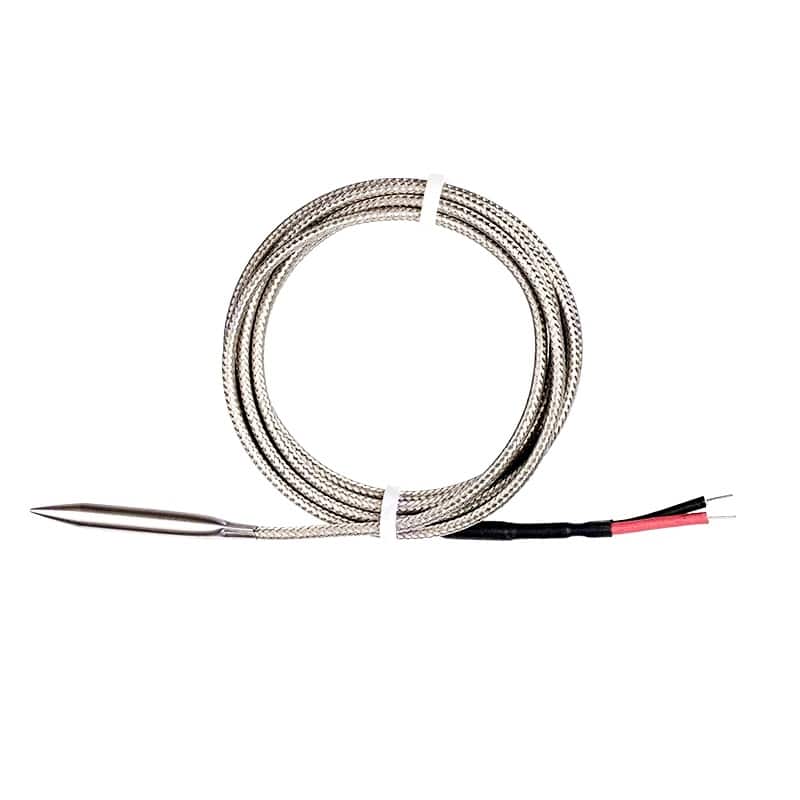

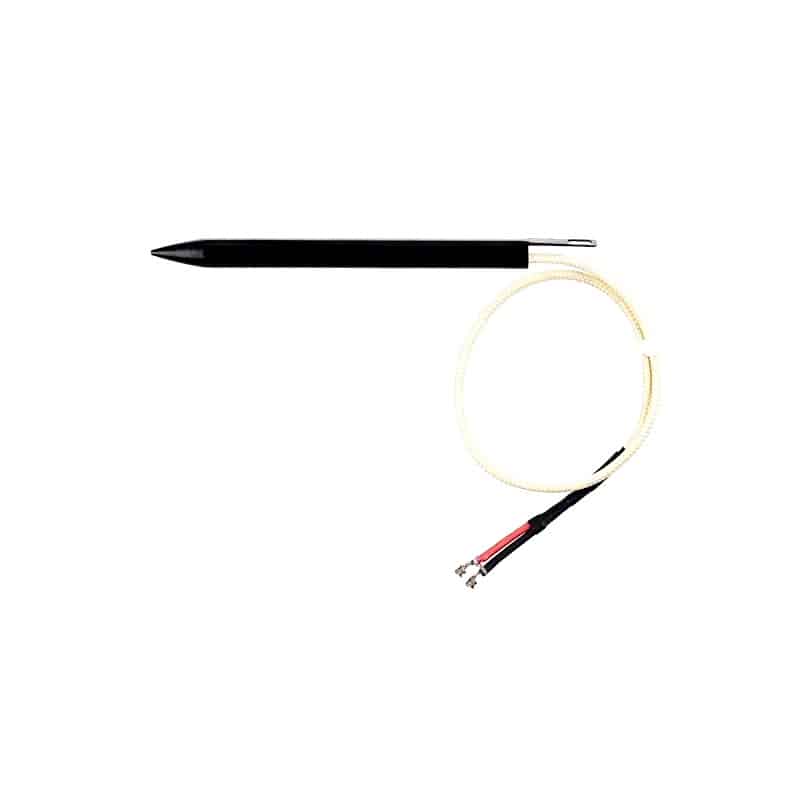

It is used for thermocouples to measure temperature. One end is directly used to measure the temperature of the object which called the work side (also called the measurement side), and the rest end is called the cold side(also called the compensation side). The cold side is connected to the display or mating meter, and the display meter will indicate the thermoelectric potential generated by the thermocouples.

The Different Types of K-Type Industrial Oven Thermocouple

Thermocouples come in combinations of different metals or “gradations”. The most common are “base metal” thermocouples of types J, K, T, E, and N. There are also special types of thermocouples called noble metal thermocouples, including Types R, S, and B. The highest temperature thermocouple types are refractory thermocouples, including types C, G, and D.

The Advantages of K-Type Industrial Oven Thermocouple

- As one kind of temperature sensor, K-type thermocouples are usually used in conjunction with display meters, recording meters and electronic regulators which can directly measure the surface temperature of liquid vapor and gas and solid in various production.

- K-type thermocouples have the advantages of good linearity, large thermoelectromotive force, high sensitivity, good stability and uniformity, strong anti-oxidation performance, and low price.

- The international standard of thermocouples wire is divided into first-level and second-level accuracy: the first-level accuracy error is ±1.1℃ or ±0.4%, and the second-level accuracy error is ±2.2℃ or ±0.75%; the accuracy error is the maximum value that picked from the two.

The Features of K-Type Industrial Oven Thermocouple

| Working Temperature Range | -50℃~+482℃ |

|---|---|

| First-level Accuracy | ±0.4% or ±1.1℃ |

| Response Speed | MAX.5sec |

| Insulation Voltage | 1800VAC,2sec |

| Insulation Resistance | 500VDC ≥100MΩ |

The Applications of IK-Type Industrial Oven Thermocouple

Grill, baked oven, industrial equipment