Understanding PT100 IEC Standards

PT100 IEC is a crucial term in the world of temperature sensing technology. PT100 refers to a type of platinum resistance temperature sensor, and IEC stands for the International Electrotechnical Commission. In this article, we will delve into the significance of PT100 IEC in the context of NTC (Negative Temperature Coefficient) thermistors.

The Versatility of NTC Thermistors

NTC thermistors are temperature-sensitive resistors that exhibit a decrease in resistance as temperature rises. They are widely used in various applications, including temperature measurement, control systems, and industrial processes. PT100 IEC, although different in construction and operation, shares the same goal of providing accurate temperature readings.

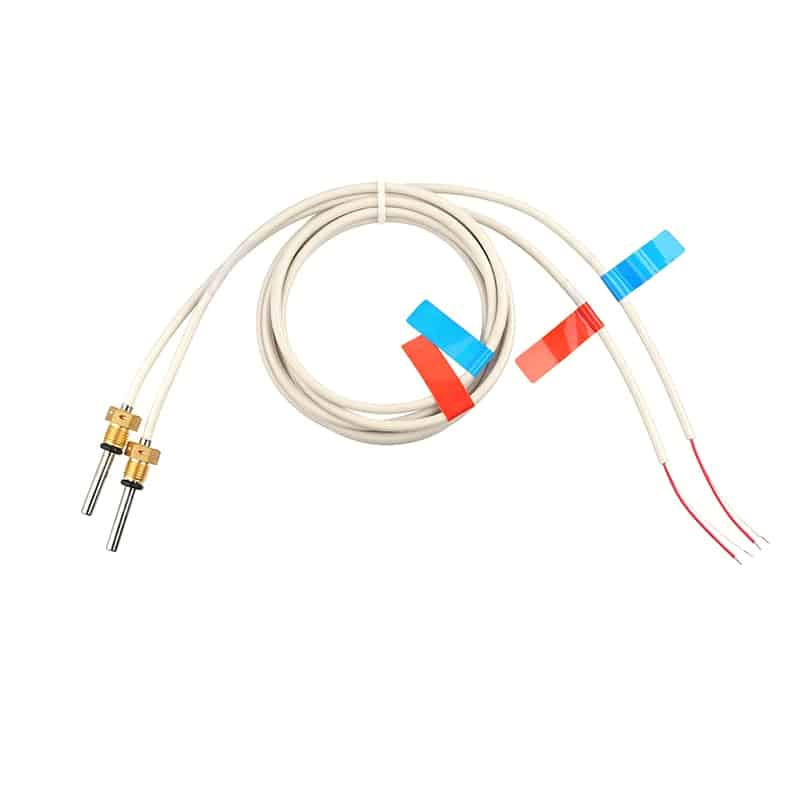

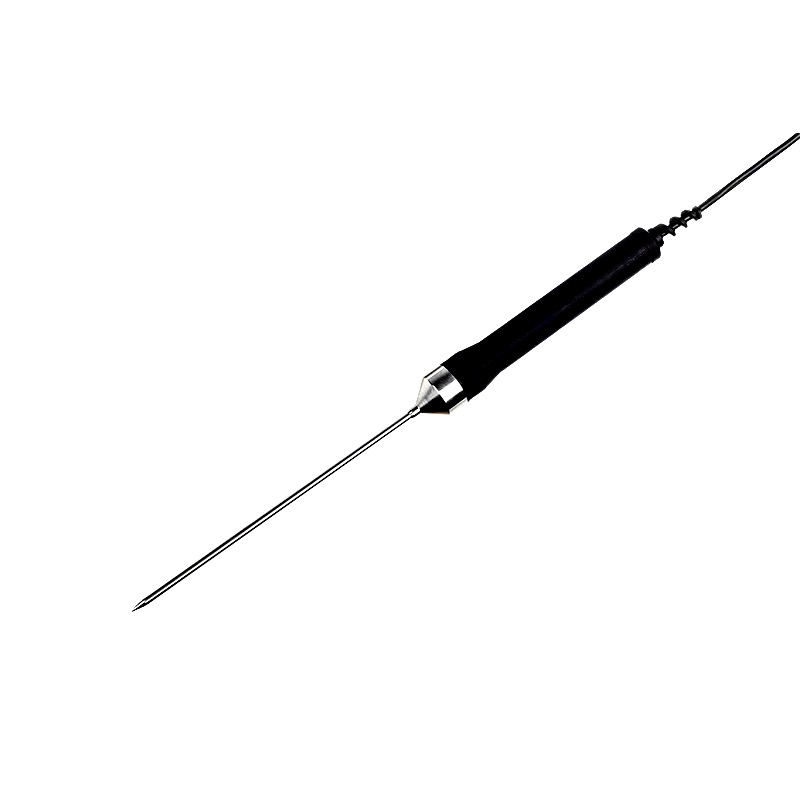

StarLight is a high-tech enterprise integrating R&D, production, and sales of NTC thermistors, NTC temperature sensors, thermocouple temperature sensors, platinum resistance temperature sensors, LPTC/KTY temperature sensors, DS18B20 digital temperature sensors, temperature, and humidity sensors.

PT100 IEC vs. NTC Thermistors

One key distinction between PT100 IEC and NTC thermistors lies in their resistance-temperature characteristics. While NTC thermistors have a negative temperature coefficient, PT100 IEC operates based on the linear relationship between resistance and temperature.

IEC Standards for Precision

PT100 IEC sensors adhere to strict international standards defined by the IEC, ensuring precision and reliability in temperature measurements. These sensors are commonly used in critical applications where accuracy is paramount, such as scientific research, pharmaceuticals, and aerospace.

Applications of PT100 IEC

PT100 IEC sensors find applications in scenarios where precise temperature monitoring is essential. Their compatibility with standardized measurement systems makes them a preferred choice in laboratories, climate control systems, and medical devices.

In conclusion, PT100 IEC and NTC thermistors play vital roles in temperature sensing technology, each with its unique characteristics and applications. Whether you require high precision or versatility, understanding these technologies is essential for making informed decisions in temperature measurement and control.