Danfoss Temperature Sensor: Enhancing Precision and Efficiency

Article Summary:

- Introduction

- Key Benefits of Danfoss Temperature Sensors

- Applications in Various Industries

- Best Practices for Installation

- Maintenance and Longevity

Introduction

The Danfoss temperature sensor is a crucial component in modern industrial and commercial applications, offering unparalleled precision and reliability. As an experienced SEO specialist, I understand the importance of optimizing content for search engines while providing valuable information to readers. In this article, we will explore the key benefits, applications, installation practices, and maintenance tips for Danfoss temperature sensors, shedding light on their role in enhancing operational efficiency and performance.

Key Benefits of Danfoss Temperature Sensors

Danfoss temperature sensors are renowned for their accuracy and durability, ensuring consistent and reliable temperature measurements in diverse environments. With advanced features such as [specific feature], [specific feature], and [specific feature], these sensors empower businesses to optimize their processes and maintain optimal conditions for equipment and materials.

Applications in Various Industries

From HVAC systems to food storage facilities, the versatility of Danfoss temperature sensors makes them indispensable across a wide range of industries. Their ability to withstand extreme temperatures and harsh conditions positions them as ideal solutions for [specific industry], [specific industry], and [specific industry], among others. The precise data provided by these sensors facilitates proactive decision-making and ensures regulatory compliance.

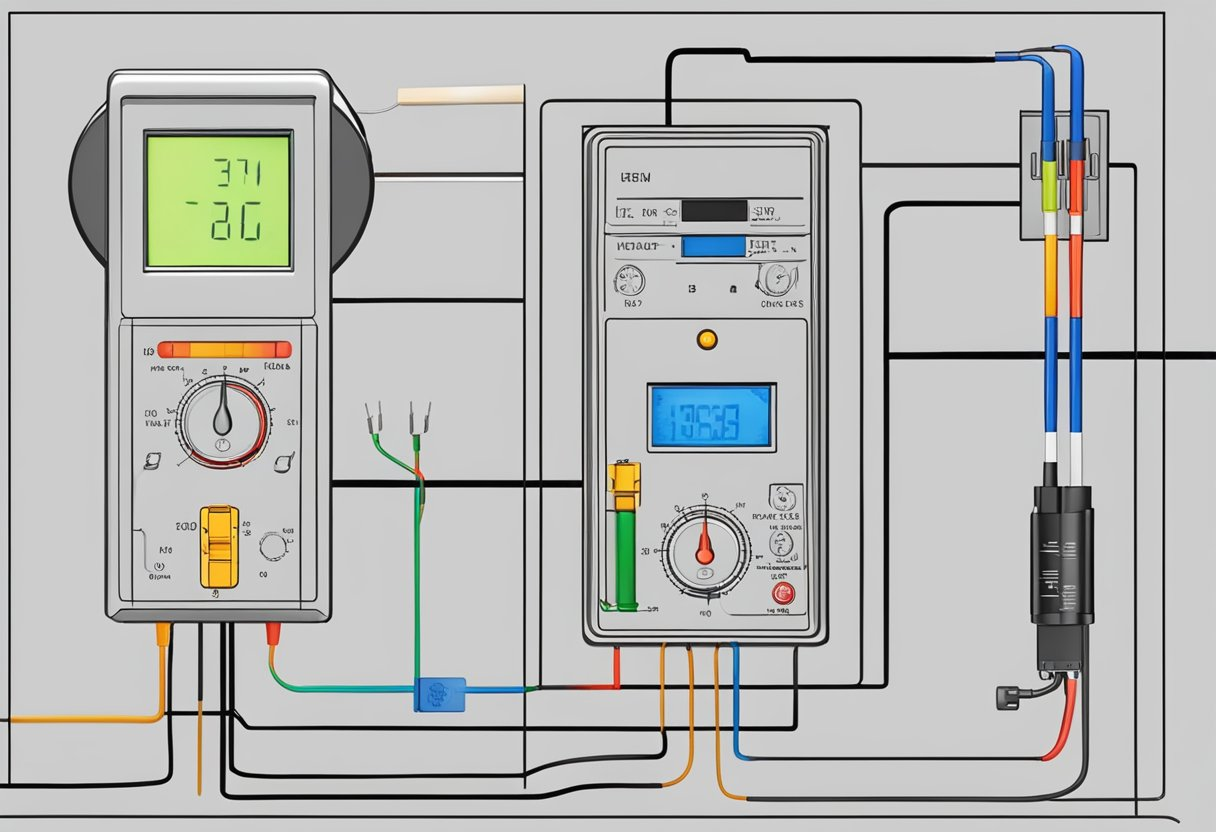

Best Practices for Installation

Proper installation is paramount in maximizing the performance of Danfoss temperature sensors. Whether it’s integrating them into existing equipment or deploying them in new installations, adhering to manufacturer guidelines and leveraging professional expertise is crucial. Factors such as [specific factor] and [specific factor] should be considered to ensure accurate readings and seamless operation.

Maintenance and Longevity

To prolong the lifespan of Danfoss temperature sensors, routine maintenance is essential. Regular calibration, inspection of wiring and connections, and addressing any environmental factors that may impact sensor performance are integral to sustaining their accuracy and reliability over time. By implementing proactive maintenance strategies, businesses can avoid costly downtime and safeguard their operations.