For Non Contact Temperature Measurement: The Ultimate Guide to Achieving Accurate Results

Article Summary:

1. Introduction

2. Understanding Non Contact Temperature Measurement

3. Advantages of Non Contact Temperature Measurement

4. Applications and Industries Using Non Contact Temperature Measurement

5. Factors Affecting Accuracy in Non Contact Temperature Measurement

6. Best Practices for Achieving Accurate Results

7. Conclusion

Introduction:

In today’s fast-paced world, accurate temperature measurement is essential in various industries and applications. Traditional contact-based temperature measurement methods often pose limitations and challenges, leading to the increased demand for non-contact temperature measurement solutions. In this comprehensive guide, we will delve into the world of non-contact temperature measurement, exploring its benefits, applications, factors affecting accuracy, and best practices to achieve reliable and precise results.

Understanding Non Contact Temperature Measurement:

Non-contact temperature measurement, as the name suggests, enables temperature detection without direct physical contact with the object or surface being measured. This method relies on the principles of thermal radiation and infrared technology to capture and analyze the emitted energy from an object, converting it into a temperature reading. By utilizing sophisticated sensors and advanced algorithms, non-contact temperature measurement devices provide quick and accurate results, making them highly valuable in a wide range of industries.

Advantages of Non Contact Temperature Measurement:

Non-contact temperature measurement offers several advantages over traditional contact-based methods. Firstly, it eliminates the need for physical contact, ensuring safety and preventing contamination or damage to delicate surfaces. Secondly, non-contact devices can measure temperatures from a distance, enabling measurements in hard-to-reach or hazardous areas. Additionally, non-contact temperature measurement is non-invasive, making it ideal for monitoring temperature changes in live organisms or sensitive materials. Lastly, these devices provide real-time results, facilitating efficient and timely decision-making processes.

Applications and Industries Using Non Contact Temperature Measurement:

Non-contact temperature measurement finds applications in numerous industries, ranging from healthcare and manufacturing to food processing and HVAC systems. In the medical field, it is widely utilized for body temperature screening, fever detection, and clinical research. Industrial sectors employ non-contact temperature measurement for preventive maintenance, quality control, and process monitoring. Furthermore, it plays a crucial role in automotive, aerospace, and energy sectors to ensure optimal performance and safety of machinery and equipment.

Factors Affecting Accuracy in Non Contact Temperature Measurement:

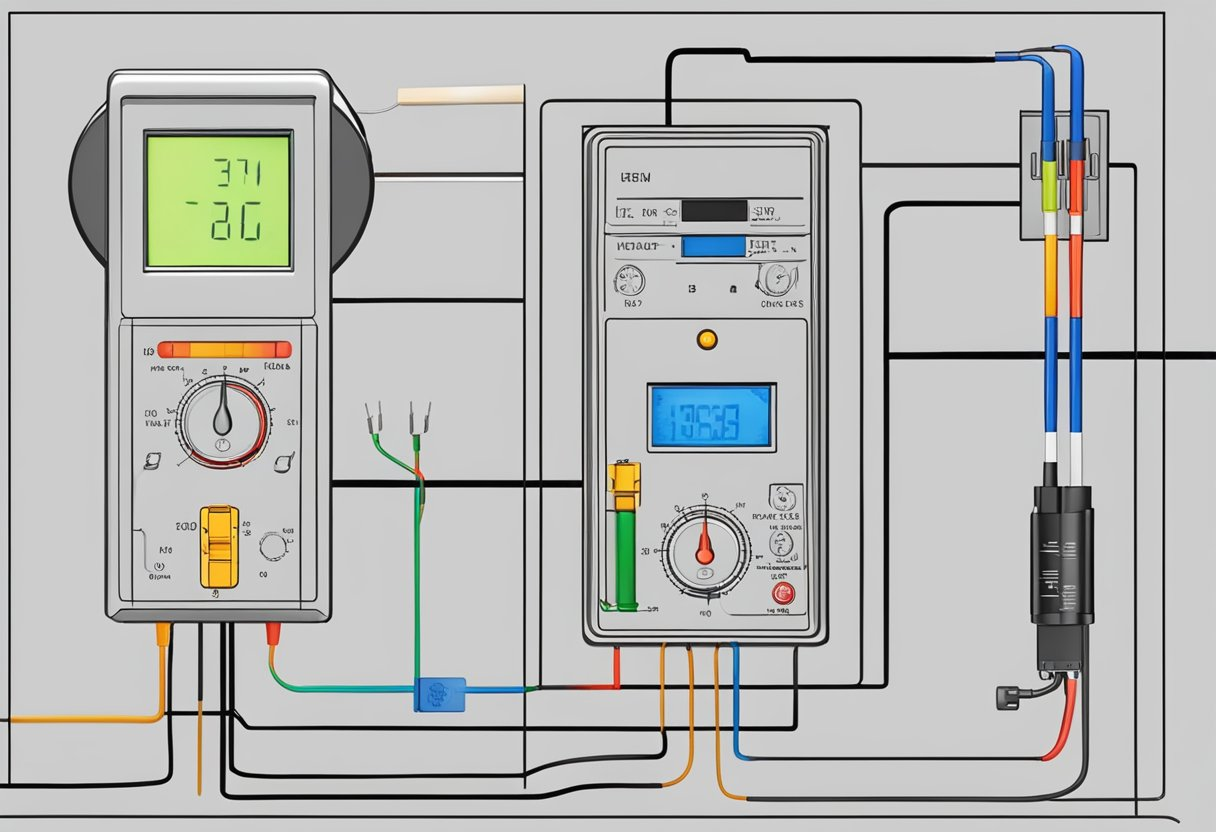

While non-contact temperature measurement offers unparalleled convenience, several factors can influence its accuracy. Calibration, emissivity, distance-to-spot ratio, ambient conditions, and environmental interference are among the key factors that need careful consideration. Ensuring proper calibration and understanding the characteristics of the target surface, such as emissivity, enables accurate temperature readings. Additionally, maintaining an appropriate distance-to-spot ratio, accounting for ambient conditions, and minimizing environmental interferences play vital roles in achieving reliable results.

Best Practices for Achieving Accurate Results:

To maximize the accuracy of non-contact temperature measurement, following best practices is crucial. Firstly, understanding the device’s specifications and limitations is essential, allowing you to optimize its performance. Secondly, selecting the appropriate measurement mode and adjusting the emissivity settings based on the object being measured significantly impacts accuracy. Moreover, controlling the ambient conditions, such as minimizing dust or smoke particles, ensures precise readings. Lastly, regular maintenance, including cleaning and calibration, guarantees consistent and reliable measurements.

Conclusion:

Non-contact temperature measurement has revolutionized temperature monitoring across industries, offering numerous advantages and precise results. By leveraging thermal radiation and infrared technology, these devices provide a safe, efficient, and accurate means of temperature measurement. Understanding the principles, applications, and best practices outlined in this guide will empower you to make informed decisions when implementing non-contact temperature measurement solutions in your industry. Embrace this cutting-edge technology and unlock its potential for enhanced productivity, quality, and safety.

The Rise of Smart Home Temperature Sensors: Chinese Manufacturers Leading the Future of Home Automation

The integration of smart home technology has transformed daily living, making homes more efficient and responsive. As consumers increasingly seek comfort and convenience, smart home temperature sensors have emerged as