Unlocking the Potential of Industrial Temperature Meter for Precise Environmental Monitoring

Article Summary

Introduction

As technology continues to advance, the use of industrial temperature meters has become increasingly crucial in ensuring precise environmental monitoring across various industries. From manufacturing facilities to research laboratories, the accurate measurement of temperature is integral to maintaining optimal working conditions and product quality. In this comprehensive guide, we will delve into the significance of industrial temperature meters and explore their diverse applications, features, and installation considerations.

The Importance of Industrial Temperature Meters

Industrial temperature meters play a pivotal role in safeguarding operational efficiency and product integrity. By providing real-time temperature data, these devices enable proactive decision-making and help prevent costly equipment failures or production errors. Moreover, they contribute to regulatory compliance by ensuring that environmental conditions adhere to industry standards and safety protocols.

Key Features to Consider

When selecting an industrial temperature meter, it’s imperative to assess a range of features to meet specific operational requirements. Factors such as accuracy, response time, connectivity options, and durability should be carefully evaluated to ensure seamless integration with existing infrastructure and reliable performance in demanding environments.

Installation and Maintenance

Proper installation and regular maintenance are fundamental to maximizing the effectiveness of industrial temperature meters. Whether deploying wired or wireless solutions, meticulous attention to placement and calibration is essential for obtaining precise temperature readings. Additionally, adherence to scheduled maintenance routines prolongs the lifespan of these instruments and minimizes potential disruptions to monitoring operations.

Applications in Various Industries

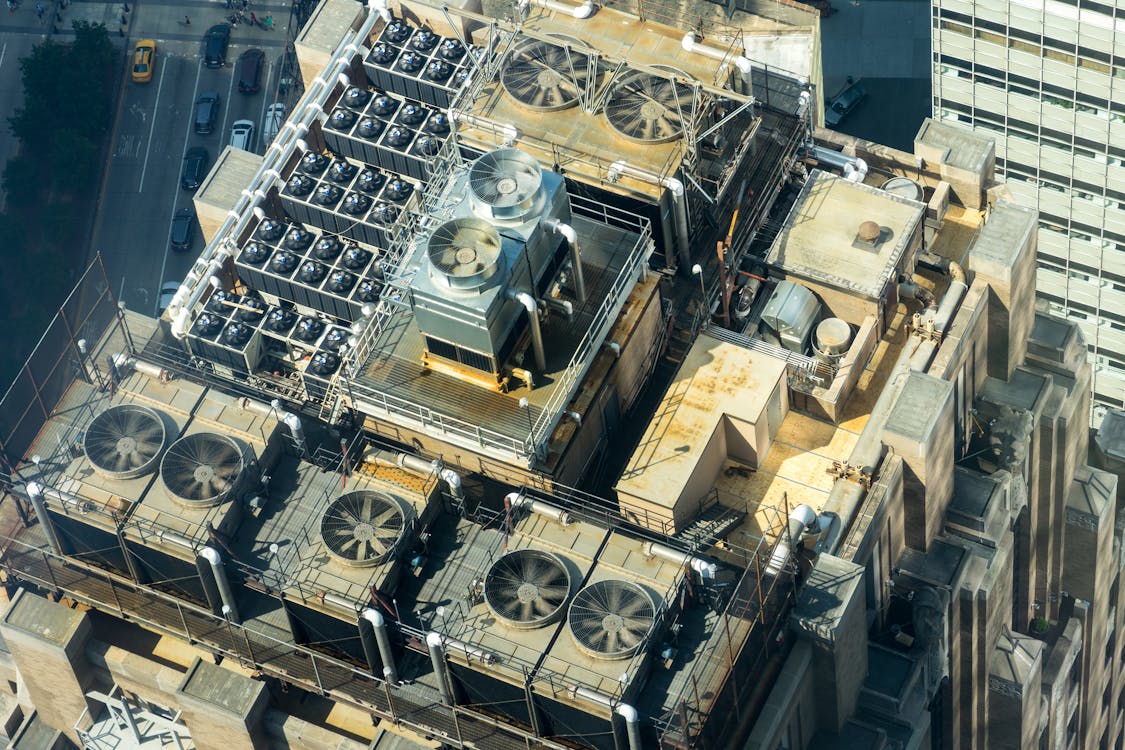

The versatility of industrial temperature meters extends across a spectrum of industries, including but not limited to pharmaceuticals, food and beverage, chemical processing, and HVAC systems. Their applicability ranges from ensuring compliant storage conditions for perishable goods to monitoring optimal temperatures in critical manufacturing processes, highlighting the indispensable role they play in preserving product quality and operational efficiency.

Conclusion

In conclusion, the utilization of industrial temperature meters is integral to maintaining precise environmental monitoring in diverse industrial settings. By leveraging the advanced capabilities and insights provided by these devices, organizations can uphold stringent quality standards, mitigate risks, and optimize operational performance. Investing in the right industrial temperature meter is not only a strategic asset but a commitment to enhancing overall safety and productivity.