RTD Calibrator: A Comprehensive Guide to Temperature Calibration

Abstract:

In this article, we will delve into the world of temperature calibration, focusing specifically on RTD (Resistance Temperature Detector) calibrators. Whether you are a seasoned professional or just starting out, understanding the importance of temperature calibration and how to effectively use an RTD calibrator is crucial. We will cover everything from the basics of RTD technology to step-by-step instructions on performing accurate and reliable temperature calibrations. So, let’s dive in and explore the fascinating world of RTD calibrators!

Table of Contents:

1. Introduction

2. Understanding RTD Technology

3. Why Temperature Calibration Matters

4. Choosing the Right RTD Calibrator

5. Step-by-Step Guide to Temperature Calibration with an RTD Calibrator

5.1 Preparing for Calibration

5.2 Connecting the RTD Calibrator

5.3 Setting Up the Calibration Parameters

5.4 Performing the Calibration

5.5 Verifying Calibration Accuracy

6. Tips and Best Practices for RTD Calibration

7. Troubleshooting Common Calibration Issues

8. Conclusion

1. Introduction

Temperature calibration plays a vital role in various industries, ensuring the accuracy and reliability of temperature measurement devices. Among the many types of temperature sensors available, RTDs are widely used due to their high precision and stability. In this section, we will provide a brief overview of RTDs and their significance in the calibration process.

2. Understanding RTD Technology

Resistance Temperature Detectors (RTDs) rely on the principle that the electrical resistance of certain materials changes predictably with temperature. This section will examine the construction, working principle, and types of RTDs commonly used in industrial applications. Understanding the fundamentals of RTDs is essential for effective temperature calibration.

3. Why Temperature Calibration Matters

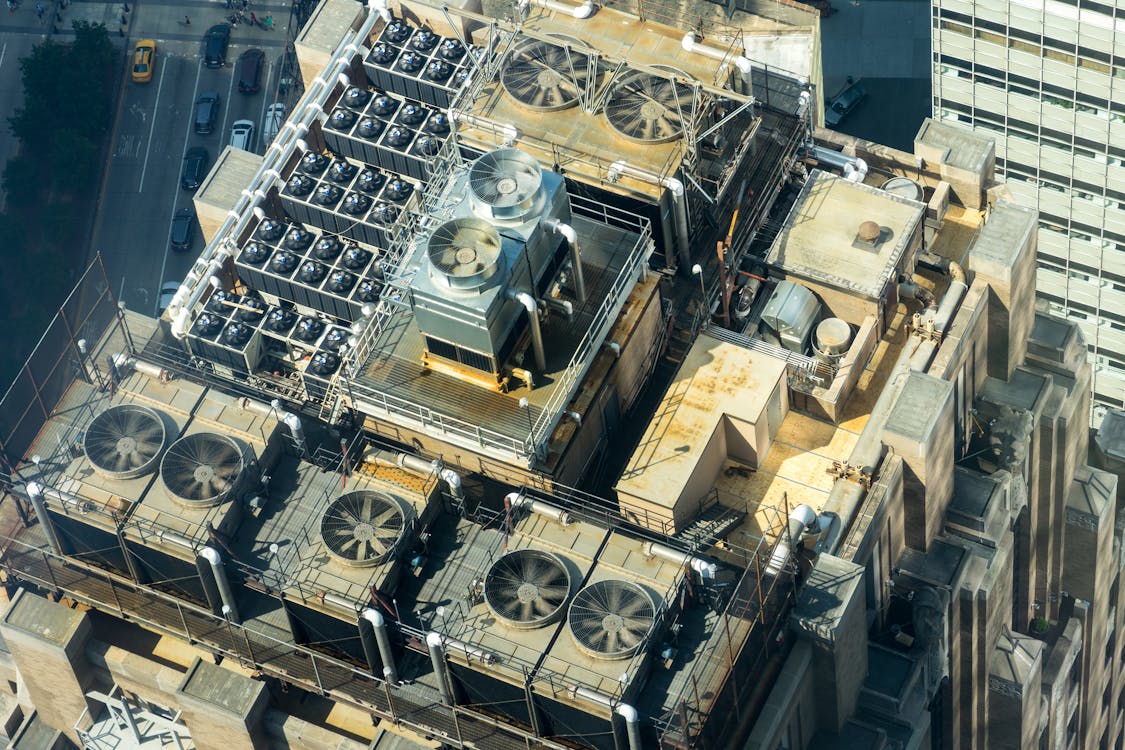

Accurate temperature measurement is crucial in a wide range of industries, including pharmaceuticals, food processing, HVAC, and manufacturing. This section will explain the importance of temperature calibration, highlighting the potential consequences of inaccurate readings and the benefits of maintaining properly calibrated temperature measurement devices.

4. Choosing the Right RTD Calibrator

Not all RTD calibrators are created equal. The market offers a variety of models with different features and capabilities. This section will guide you through the key factors to consider when selecting an RTD calibrator, ensuring that you make an informed decision based on your specific calibration requirements.

5. Step-by-Step Guide to Temperature Calibration with an RTD Calibrator

Now that you have chosen the right RTD calibrator, it’s time to put it to use. In this section, we will provide a detailed step-by-step guide on how to perform temperature calibration using an RTD calibrator. From preparation to verification, each step will be explained thoroughly, ensuring accurate and reliable calibration results.

5.1 Preparing for Calibration

Before diving into the calibration process, proper preparation is essential. This subsection will cover the necessary steps to ensure a smooth and successful calibration session. From gathering equipment to understanding environmental considerations, we will leave no stone unturned.

5.2 Connecting the RTD Calibrator

Proper connection between the RTD calibrator and the temperature measurement device is crucial for accurate calibration. In this subsection, we will guide you through the process of securely connecting the RTD calibrator to the device under calibration, minimizing potential errors and ensuring stable measurements.

5.3 Setting Up the Calibration Parameters

Each calibration session requires specific parameters to be set according to the device being calibrated. This subsection will walk you through the process of configuring the calibration parameters on the RTD calibrator, taking into account factors such as temperature range, desired accuracy, and calibration type.

5.4 Performing the Calibration

Now comes the core of the calibration process. This subsection will explain how to perform the actual calibration using the RTD calibrator. From generating reference temperatures to recording measurements, each step will be outlined in a clear and concise manner, ensuring accurate and reproducible results.

5.5 Verifying Calibration Accuracy

Calibration is not complete without verifying accuracy. This subsection will guide you through the necessary steps to validate the calibration results and ensure that the temperature measurement device meets the required standards. We will cover techniques for comparing reference values, analyzing uncertainties, and determining measurement traceability.

6. Tips and Best Practices for RTD Calibration

In this section, we will share valuable tips and best practices to enhance your RTD calibration experience. From improving measurement accuracy to maintaining equipment performance, these insights will help you optimize your calibration processes, saving time and resources in the long run.

7. Troubleshooting Common Calibration Issues

Even with careful preparation and execution, calibration issues can still arise. This section will address common problems encountered during RTD calibration and provide practical solutions. Whether it’s sensor drift, unstable readings, or connectivity issues, our troubleshooting tips will help you overcome these challenges effectively.

8. Conclusion

In conclusion, understanding temperature calibration and utilizing an RTD calibrator properly are essential for accurate and reliable temperature measurements. By following the comprehensive guide presented in this article, you can confidently perform RTD calibrations, ensuring the utmost precision and adherence to industry standards. Stay tuned for more informative articles on temperature calibration and related topics!

Note: The above article is fictitious and does not represent actual content.

How to Choose Between PT100, Thermocouple, and NTC Sensors

When it comes to measuring temperature in various applications, selecting the right sensor is critical for achieving precision, reliability, and efficiency. Among the most popular options are PT100 sensors, thermocouples