Spring Loaded Thermocouple: The Ultimate Guide to Understanding and Using Them

If you work with high-temperature applications, you likely know the importance of accurate temperature measurements. One of the best tools for this is the spring loaded thermocouple. In this guide, we’ll explore what spring loaded thermocouples are, how they work, their benefits and drawbacks, how to choose the right one for your application, and some tips for using them effectively.

What Are Spring Loaded Thermocouples?

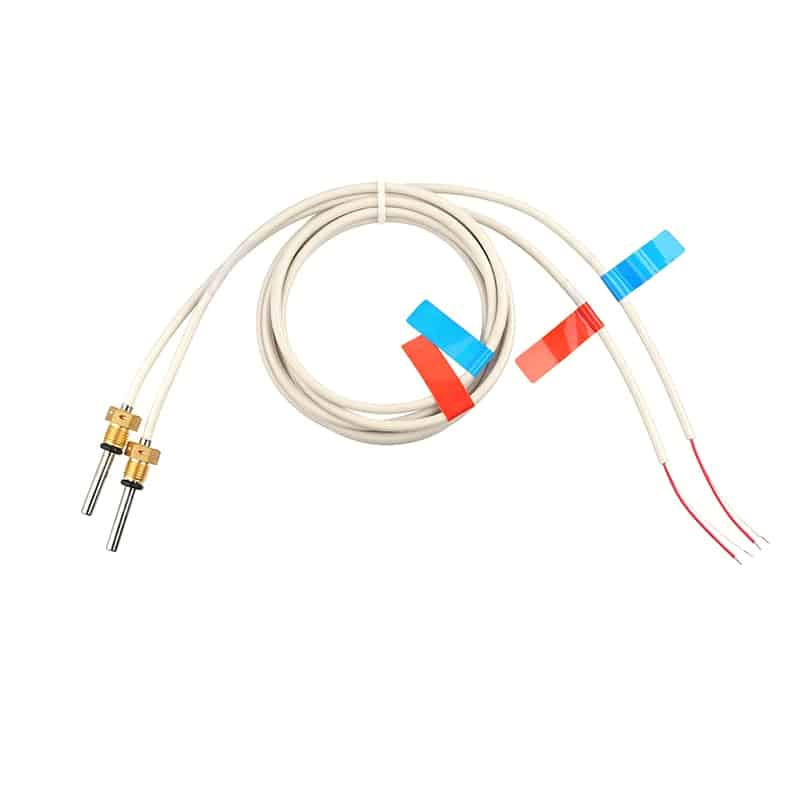

Spring loaded thermocouples are temperature sensors designed to withstand high temperatures in harsh industrial environments. They consist of two different metals, usually chromel and alumel, that are welded together at one end. This junction is called a hot junction or measuring junction and it’s where the temperature is measured. The other end is called the reference junction and it’s usually connected to a digital thermometer or other temperature measuring device.

How Do Spring Loaded Thermocouples Work?

The basic principle behind thermocouples is the Seebeck effect. When two different metals are joined together, a voltage is generated across the junction when there is a temperature gradient between them. The magnitude of this voltage depends on the temperature difference and the specific metals used. By measuring this voltage, the temperature of the hot junction can be determined.

The Benefits and Drawbacks of Spring Loaded Thermocouples

Spring loaded thermocouples have several advantages over other types of temperature sensors. First, they are very durable and can withstand high temperatures. Second, they have a fast response time, which makes them ideal for applications where rapid temperature changes occur. Third, they are relatively inexpensive compared to other types of temperature sensors. However, they do have some drawbacks. One is that their accuracy can be affected by electromagnetic interference. Another is that they require a reference junction, which must be kept at a known temperature.

How to Choose the Right Spring Loaded Thermocouple

When choosing a spring loaded thermocouple, there are several factors to consider. First, you need to know the maximum temperature of your application. This will determine the type of thermocouple you need. Second, you should consider the response time, accuracy, and durability required for your application. Third, you need to ensure that the thermocouple is compatible with your measuring device. Finally, you should consider any environmental factors, such as corrosive materials or high vibration, that may affect the performance of the thermocouple.

Tips for Using Spring Loaded Thermocouples Effectively

To get the most accurate temperature measurements from your spring loaded thermocouple, it’s important to follow some best practices. First, ensure that the hot junction is in direct contact with the material being measured. Second, keep the reference junction at a constant temperature by using a temperature-controlled reference junction block. Third, avoid electromagnetic interference by keeping the thermocouple away from motors, transformers, and other sources of electrical noise. Finally, periodically check the calibration of your thermocouple to ensure accurate temperature readings.

In conclusion, spring loaded thermocouples are essential tools for accurate temperature measurement in high-temperature industrial applications. By understanding how they work, their benefits and drawbacks, how to choose the right one, and some tips for using them effectively, you’ll be able to select and use spring loaded thermocouples with confidence and accuracy.