Temperature Gauge Types: A Comprehensive Guide to Monitoring Temperature

Introduction:

In today’s digital age, where information is just a click away, it’s crucial for bloggers and website owners to understand the importance of optimizing their content for search engines. To enhance visibility on Google and attract a wider audience, one must pay attention to search engine optimization (SEO) techniques. In this article, we will delve into the topic of temperature gauge types – a key keyword – and explore various aspects of monitoring temperature, while ensuring our content is both engaging and optimized.

Table of Contents:

1. Introduction

2. Understanding Temperature Gauges

3. Benefits of Temperature Monitoring

4. Different Types of Temperature Gauges

4.1 Analog Temperature Gauges

4.2 Digital Temperature Gauges

4.3 Bi-Metallic Temperature Gauges

4.4 Liquid-Filled Temperature Gauges

5. Factors to Consider When Choosing a Temperature Gauge

6. Maintenance and Calibration of Temperature Gauges

7. Conclusion

Understanding Temperature Gauges:

Temperature gauges are invaluable devices used to measure and monitor temperature variations accurately. Whether you’re working in a laboratory, industrial setting, or even a home kitchen, understanding the different types of temperature gauges available can greatly aid in maintaining optimal conditions and preventing potential hazards.

Benefits of Temperature Monitoring:

Accurate temperature monitoring plays a crucial role in multiple industries, from ensuring product quality in manufacturing processes to guaranteeing food safety in restaurants. By closely monitoring temperature changes, businesses can identify and mitigate risks, prevent equipment malfunctions, and maintain operational efficiency. Temperature gauges serve as the eyes that never blink, allowing precise control over various processes.

Different Types of Temperature Gauges:

2.1 Analog Temperature Gauges:

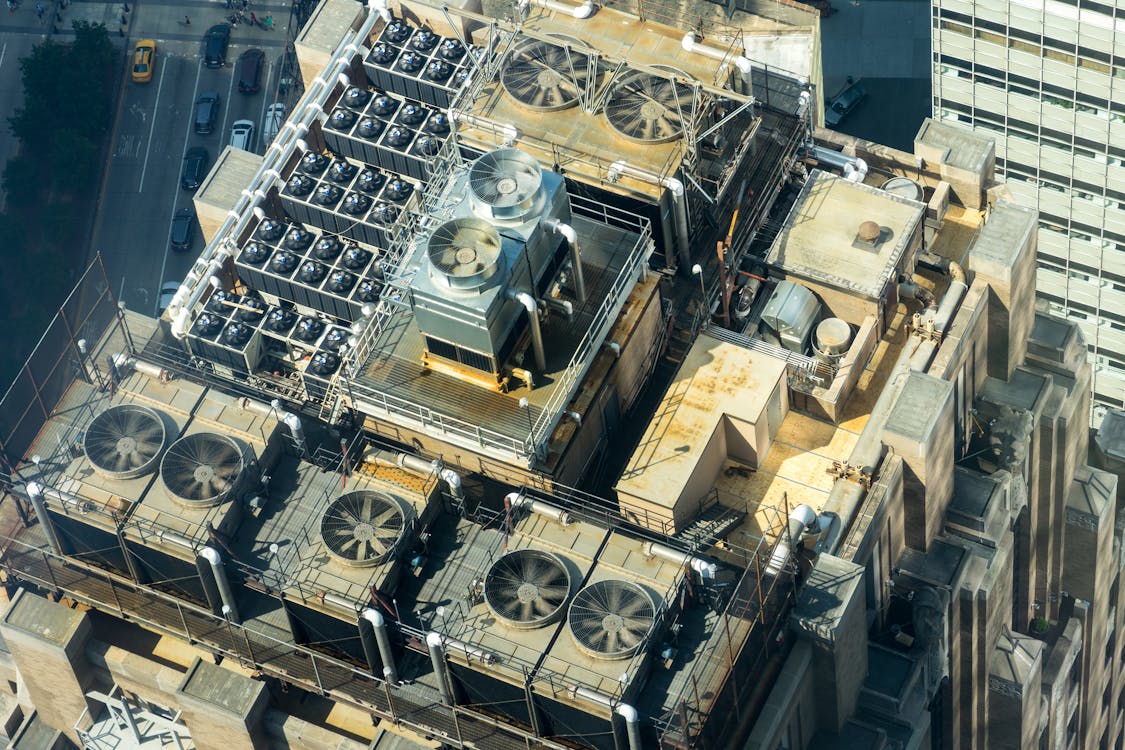

Analog temperature gauges, also known as dial gauges, have been widely used for decades. These gauges feature a dial with a needle that points to the current temperature. They are simple to use and provide a quick visual representation of temperature fluctuations. Analog temperature gauges are commonly found in industrial machinery, HVAC systems, and home appliances.

2.2 Digital Temperature Gauges:

With advancements in technology, digital temperature gauges have become increasingly popular. Equipped with digital displays, these gauges offer precise measurements and advanced features such as data logging and alarms. Digital temperature gauges are widely utilized in scientific laboratories, medical facilities, and research environments.

2.3 Bi-Metallic Temperature Gauges:

Bi-metallic temperature gauges operate on the principle of two different metals expanding at different rates when exposed to temperature changes. This expansion causes a dial or pointer to move, indicating the temperature. Bi-metallic gauges are known for their accuracy, durability, and resistance to vibration, making them suitable for industrial applications.

2.4 Liquid-Filled Temperature Gauges:

Liquid-filled temperature gauges contain a liquid, typically glycerin or silicone oil, which acts as a damping agent. This liquid absorbs vibrations, providing shock resistance and enhancing gauge accuracy. These gauges are commonly used in industries with high vibration levels, such as automotive, aerospace, and marine.

Factors to Consider When Choosing a Temperature Gauge:

When selecting a temperature gauge, several factors come into play. It’s important to consider the operating temperature range, accuracy requirements, environmental conditions, and specific application needs. By understanding these factors, you can make an informed decision and choose the most suitable temperature gauge for your requirements.

Maintenance and Calibration of Temperature Gauges:

To ensure the continued accuracy and reliability of your temperature gauges, regular maintenance and calibration are essential. Periodic maintenance includes cleaning, inspection, and testing of the gauge. Calibration ensures that the gauge provides accurate readings and adjusts any deviations. Regular maintenance and calibration help prolong the lifespan of temperature gauges and minimize measurement errors.

Conclusion:

Temperature gauges are indispensable tools for monitoring temperature in various industries and environments. By understanding the different types of temperature gauges available and considering the factors involved in selecting the right gauge, businesses can ensure optimal performance and safety. Regular maintenance and calibration further enhance accuracy and longevity. Remember, choosing the right temperature gauge is key to maintaining control, preserving quality, and preventing potential risks.

With this comprehensive guide on temperature gauge types, you can now make informed decisions while optimizing your content for search engines. Remember to employ effective SEO strategies, such as using relevant keywords like “temperature gauge types” throughout your content, to improve your website’s visibility on search engine result pages. Happy blogging!

How to Choose Between PT100, Thermocouple, and NTC Sensors

When it comes to measuring temperature in various applications, selecting the right sensor is critical for achieving precision, reliability, and efficiency. Among the most popular options are PT100 sensors, thermocouples