Temperature Gauge with Thermowell – The Ultimate Guide

Article Summary:

In this article, we will be discussing everything you need to know about temperature gauge with thermowell. From its definition, types, uses, and advantages, we’ve got you covered! So whether you’re a beginner or an expert in the field, continue reading to learn more.

Table of Contents:

I. Introduction

II. Definition of Temperature Gauge with Thermowell

III. Types of Temperature Gauge with Thermowell

IV. Benefits of Temperature Gauge with Thermowell

V. Applications of Temperature Gauge with Thermowell

VI. Factors to Consider When Choosing a Temperature Gauge with Thermowell

VII. Conclusion

I. Introduction

Temperature measurement is an essential aspect of many industrial processes. Accurate temperature readings are necessary for maintaining safety, quality control, and improving productivity. It’s important to have a reliable temperature gauge that can accurately monitor temperature changes. One such tool is the temperature gauge with thermowell.

II. Definition of Temperature Gauge with Thermowell

A temperature gauge with thermowell is a device that consists of a temperature sensor or thermometer that is inserted into a protective tube called a thermowell. The thermowell serves as a barrier between the process medium and the temperature sensor. It protects the sensor from getting damaged by the process medium while still allowing for accurate temperature measurements.

III. Types of Temperature Gauge with Thermowell

There are various types of temperature gauges with thermowells, including bimetallic, gas-actuated, and digital thermometers. Bimetallic thermometers use two dissimilar metals that expand at different rates when exposed to heat. This expansion causes the metal strip to bend, which moves the pointer on the gauge. Gas-actuated thermometers measure temperature using the principle of the gas pressure inside a bulb. Digital thermometers use electronic sensors to measure temperature and display the results on a digital screen.

IV. Benefits of Temperature Gauge with Thermowell

One of the most significant advantages of using a temperature gauge with thermowell is that it provides accurate temperature readings even in harsh environments. The thermowell protects the temperature sensor from corrosive or abrasive media, making it ideal for use in chemical processing plants and other industrial applications. Additionally, temperature gauge with thermowells are long-lasting, easy to install, and require minimal maintenance.

V. Applications of Temperature Gauge with Thermowell

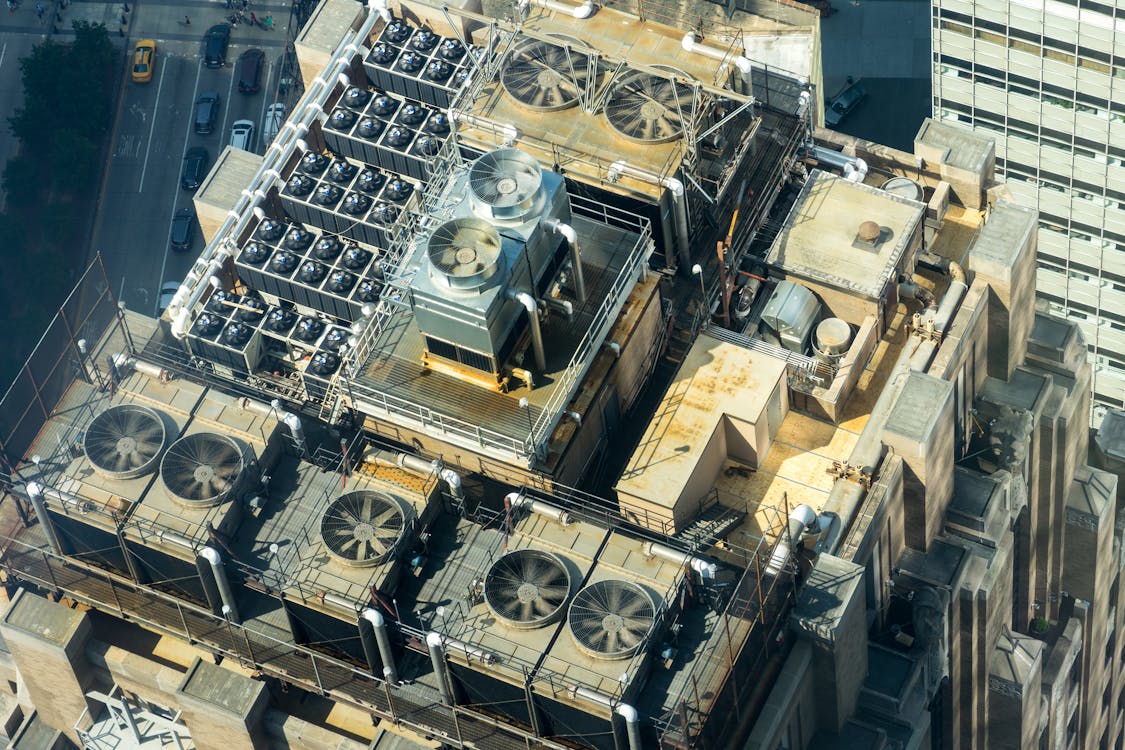

Temperature gauge with thermowells are commonly used in various industries such as oil and gas, chemical processing, food and beverage, pharmaceuticals, HVAC, and many more. They are used to monitor temperature in tanks, pipelines, reactors, and other equipment.

VI. Factors to Consider When Choosing a Temperature Gauge with Thermowell

When selecting a temperature gauge with thermowell, there are several factors that you need to consider. These include the type of process media, temperature range, accuracy requirements, and installation environment. It’s essential to choose the right type of thermometer and thermowell material to ensure that it can withstand the process conditions and provide accurate temperature readings.

VII. Conclusion

Temperature gauge with thermowells are an excellent investment for any industrial process that requires temperature measurement. They are durable, reliable, and offer accurate temperature readings even in harsh environments. Whether you’re in the oil and gas industry, chemical processing, or food and beverage, a temperature gauge with thermowell can help improve safety, quality control, and productivity. So choose wisely and invest in the right temperature gauge with thermowell for your industrial application.

How to Choose Between PT100, Thermocouple, and NTC Sensors

When it comes to measuring temperature in various applications, selecting the right sensor is critical for achieving precision, reliability, and efficiency. Among the most popular options are PT100 sensors, thermocouples