Temperature Thermistor: Exploring the World of Thermal Sensors

Abstract:

Welcome to this comprehensive guide on temperature thermistors, a fascinating field of study in the realm of thermal sensors. In this article, we will delve into the inner workings of thermistors, their applications, and how they play a crucial role in various industries. Join us as we uncover the secrets behind these innovative devices and discover how they can enhance our understanding of temperature measurements.

Table of Contents:

1. Introduction

2. What is a Temperature Thermistor?

3. How Does a Temperature Thermistor Work?

4. Types of Temperature Thermistors

4.1 NTC Thermistors

4.2 PTC Thermistors

5. Applications of Temperature Thermistors

5.1 Climate Control Systems

5.2 Medical Devices

5.3 Industrial Process Monitoring

5.4 Automotive Industry

6. Advantages and Limitations of Temperature Thermistors

7. Factors to Consider When Choosing a Temperature Thermistor

8. Tips for Proper Installation and Calibration

9. Maintenance and Troubleshooting Guide

10. Future Developments in Temperature Thermistors

11. Conclusion

1. Introduction

In a world driven by technology, precise temperature measurements are essential in countless applications. From climate control systems to medical devices, temperature thermistors serve as the backbone of temperature sensing. This article aims to provide a thorough understanding of temperature thermistors and their significance in various industries.

2. What is a Temperature Thermistor?

A temperature thermistor, short for thermal resistor, is a type of temperature sensor widely used to measure and monitor temperature variations. Unlike traditional thermometers, which rely on the expansion of liquids or solids, thermistors employ the unique characteristics of semiconductor materials to detect changes in temperature.

3. How Does a Temperature Thermistor Work?

Temperature thermistors operate based on the concept of resistance-temperature relationship. As temperature changes, the electrical resistance of the thermistor also varies. This property allows precise temperature measurements by measuring the resistance and converting it into corresponding temperature values.

4. Types of Temperature Thermistors

There are two primary types of temperature thermistors: negative temperature coefficient (NTC) and positive temperature coefficient (PTC) thermistors.

4.1 NTC Thermistors

NTC thermistors display a decrease in resistance as temperature rises. This characteristic makes them ideal for temperature monitoring applications, such as climate control and medical devices.

4.2 PTC Thermistors

Conversely, PTC thermistors exhibit an increase in resistance with temperature elevation. These thermistors find application in self-regulating heating elements, where they act as temperature limiters.

5. Applications of Temperature Thermistors

Temperature thermistors find widespread use across various industries due to their accuracy and reliability. Let’s explore some of the most notable applications:

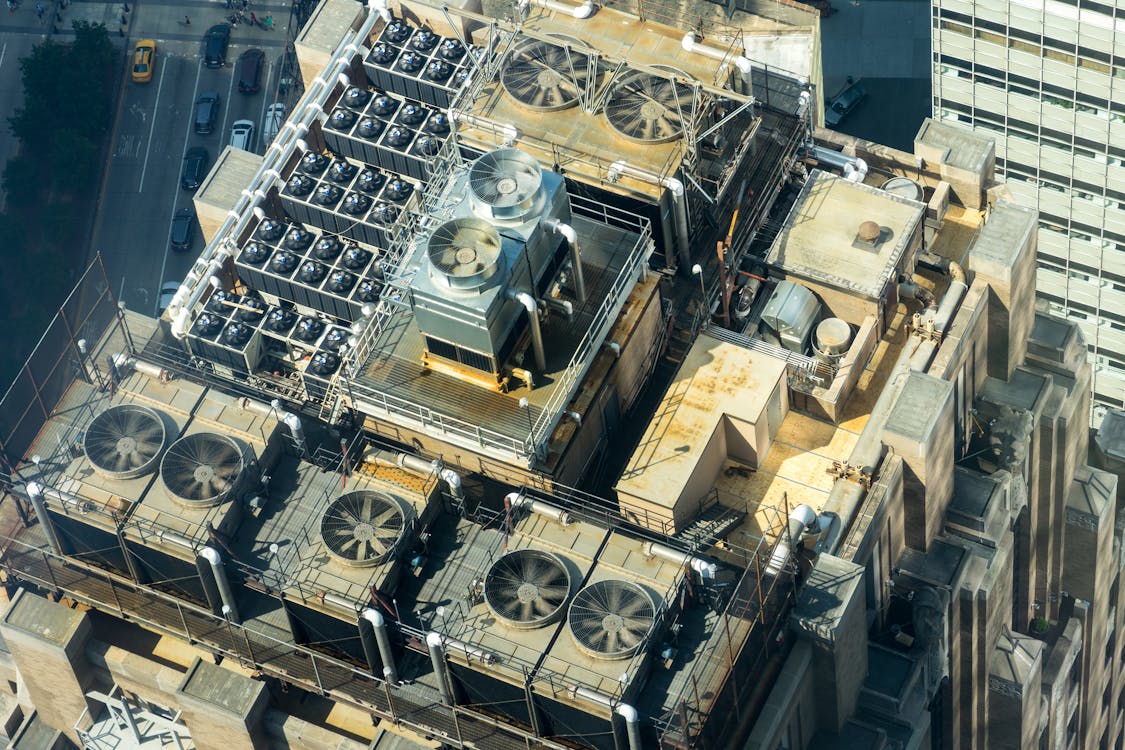

5.1 Climate Control Systems

In HVAC systems, temperature thermistors play a vital role in maintaining optimal environmental conditions. They enable precise temperature control, ensuring comfort and energy efficiency.

5.2 Medical Devices

Medical instruments heavily rely on temperature thermistors for accurate temperature readings. From body temperature monitoring to laboratory equipment, thermistors contribute to patient safety and reliable diagnostics.

5.3 Industrial Process Monitoring

Temperature-sensitive industrial processes require real-time temperature monitoring. Thermistors provide the necessary accuracy and responsiveness, ensuring efficient operation and product quality.

5.4 Automotive Industry

Automotive applications, including engine management systems and climate control, depend on temperature thermistors for precise temperature regulation. They enhance vehicle performance while ensuring passenger comfort.

6. Advantages and Limitations of Temperature Thermistors

Temperature thermistors offer several key advantages, such as high sensitivity, compact size, and cost-effectiveness. However, they also have limitations, including non-linear behavior and limited temperature range.

7. Factors to Consider When Choosing a Temperature Thermistor

When selecting a temperature thermistor for your application, factors like temperature range, accuracy requirements, response time, and environmental conditions must be considered. Each parameter plays a crucial role in determining the most suitable thermistor for your needs.

8. Tips for Proper Installation and Calibration

To ensure accurate temperature measurements, proper installation and calibration are essential. This section provides valuable insights and tips for installing and calibrating temperature thermistors effectively.

9. Maintenance and Troubleshooting Guide

Like any electronic device, temperature thermistors require regular maintenance and occasional troubleshooting. This guide offers practical advice on maintaining optimal performance and diagnosing common issues.

10. Future Developments in Temperature Thermistors

The field of temperature thermistors is continually evolving, with ongoing advancements in materials and manufacturing techniques. This section explores potential future developments and emerging trends in temperature sensing technology.

11. Conclusion

Temperature thermistors are indispensable tools for precise temperature measurements across numerous industries. Their ability to provide accurate and reliable data contributes to improved efficiency, safety, and comfort. By understanding the fundamentals of temperature thermistors and their applications, we can unlock their full potential and harness the power of temperature sensing.

How to Choose Between PT100, Thermocouple, and NTC Sensors

When it comes to measuring temperature in various applications, selecting the right sensor is critical for achieving precision, reliability, and efficiency. Among the most popular options are PT100 sensors, thermocouples