Water Temperature Switch: The Key to Efficient and Reliable Systems

Abstract:

In this article, we will explore the importance of a water temperature switch in various systems and how it contributes to their efficiency and reliability. From heating and cooling systems to industrial processes, understanding the role of a water temperature switch is crucial for optimal performance. This comprehensive guide will delve into the functionalities and benefits of a water temperature switch, its applications, and provide practical tips for choosing and maintaining one.

Table of Contents:

1. Introduction

2. How Does a Water Temperature Switch Work?

3. Importance of Water Temperature Control

4. Applications of Water Temperature Switches

4.1 Heating and Cooling Systems

4.2 Industrial Processes

4.3 Automotive Industry

5. Choosing the Right Water Temperature Switch

5.1 Accuracy and Sensitivity

5.2 Compatibility with System Requirements

5.3 Durability and Environmental Factors

6. Maintaining and Troubleshooting Water Temperature Switches

6.1 Regular Inspections and Cleanings

6.2 Calibration and Adjustment

6.3 Common Issues and Solutions

7. Conclusion

1. Introduction:

Water temperature plays a crucial role in many systems, from ensuring comfort in HVAC systems to maintaining optimal operating conditions in industrial processes. A water temperature switch serves as a critical component in monitoring and controlling this essential factor. In this article, we will explore the functions and benefits of water temperature switches, their applications, and provide useful insights for choosing and maintaining them effectively.

2. How Does a Water Temperature Switch Work?

A water temperature switch operates on the principle of thermal expansion and contraction. It consists of a sensor that detects changes in water temperature and triggers an electrical response. When the temperature exceeds or falls below a preset threshold, the switch prompts the connected system to take appropriate action, such as activating or deactivating a heating or cooling mechanism. This allows for precise temperature control and ensures optimal system performance.

3. Importance of Water Temperature Control:

Accurate water temperature control is vital in various systems for several reasons. Firstly, it enables energy efficiency by preventing unnecessary operation of heating or cooling components when the desired temperature range is already achieved. Additionally, maintaining consistent water temperature contributes to system longevity by reducing wear and tear caused by frequent temperature fluctuations. Moreover, it ensures occupant comfort, process stability, and prevents damage to sensitive equipment or materials.

4. Applications of Water Temperature Switches:

4.1 Heating and Cooling Systems:

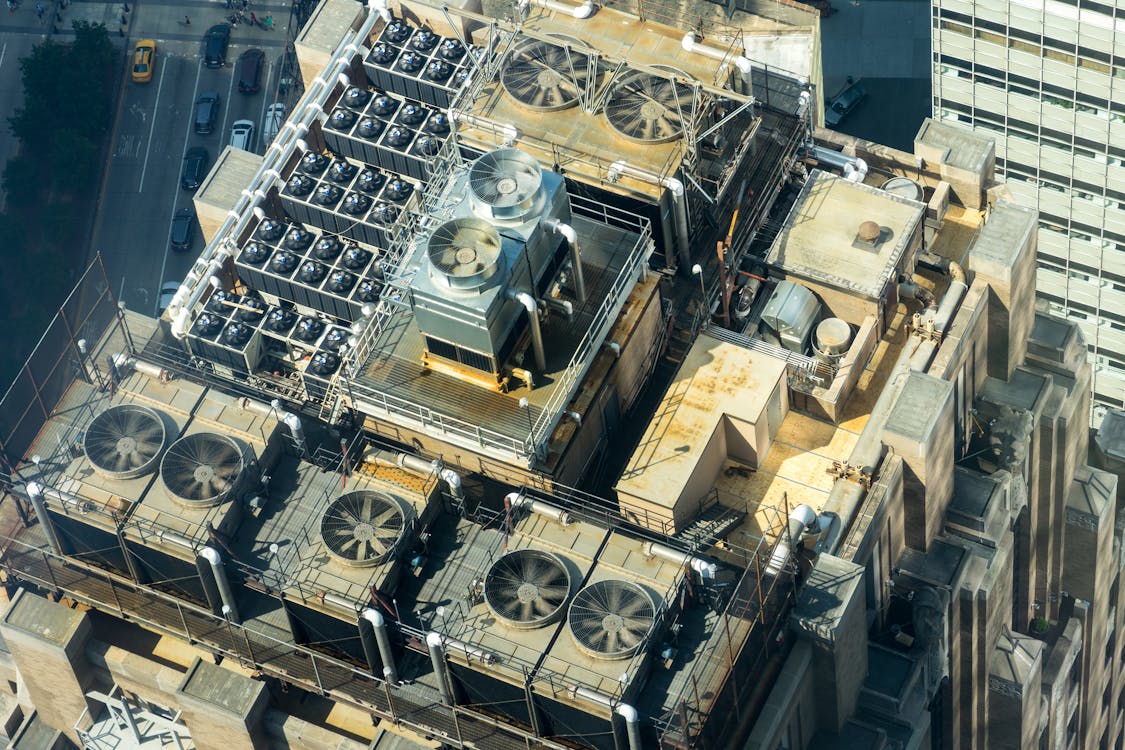

Water temperature switches find extensive use in HVAC systems, where they regulate the flow of heated or cooled water to maintain the desired indoor temperature. By monitoring the water temperature, these switches ensure efficient energy usage and provide optimal comfort levels.

4.2 Industrial Processes:

In industrial settings, precise control of water temperature is critical for a wide range of processes. From chemical reactions and material processing to equipment cooling, water temperature switches play a pivotal role in maintaining the required conditions for efficient operation and product quality.

4.3 Automotive Industry:

Automobiles rely on water temperature switches to monitor engine coolant temperature and prevent overheating. These switches act as a safety measure by engaging cooling mechanisms when the temperature exceeds safe limits, thus protecting the engine from damage.

5. Choosing the Right Water Temperature Switch:

Selecting the appropriate water temperature switch for a specific application requires careful consideration of several factors.

5.1 Accuracy and Sensitivity:

For precise temperature control, it is essential to choose a switch with high accuracy and sensitivity. This ensures that any temperature fluctuations are promptly detected and addressed, preventing potential issues before they escalate.

5.2 Compatibility with System Requirements:

The selected switch must be compatible with the system’s voltage, current, and overall design. It should seamlessly integrate into the existing infrastructure without causing any disruptions or requiring major modifications.

5.3 Durability and Environmental Factors:

Consider the operating conditions, such as temperature extremes, moisture levels, and chemical exposure, when selecting a water temperature switch. Opt for switches made from robust materials that can withstand harsh environments and provide reliable performance over an extended period.

6. Maintaining and Troubleshooting Water Temperature Switches:

Regular maintenance is crucial for ensuring the longevity and accuracy of water temperature switches.

6.1 Regular Inspections and Cleanings:

Periodically inspecting the switch for any signs of damage or corrosion is essential. Clean the sensor and surrounding components to maintain accurate readings and prevent false triggers.

6.2 Calibration and Adjustment:

If the switch exhibits inconsistent readings, it may require calibration or adjustment. Consult the manufacturer’s guidelines or seek professional assistance to ensure precise temperature control.

6.3 Common Issues and Solutions:

Common issues with water temperature switches include electrical failures, sensor malfunctions, and inaccurate readings. Troubleshooting techniques, such as checking wiring connections and replacing faulty components, can help resolve these problems efficiently.

7. Conclusion:

In conclusion, a water temperature switch is a vital component in various systems, providing accurate temperature control and contributing to their efficiency and reliability. Whether it’s HVAC systems, industrial processes, or automotive applications, understanding the functionalities and benefits of water temperature switches is crucial for optimal performance. By selecting the right switch and maintaining it effectively, system operators can ensure consistent water temperature regulation, enhance energy efficiency, and prolong equipment lifespan.

How to Choose Between PT100, Thermocouple, and NTC Sensors

When it comes to measuring temperature in various applications, selecting the right sensor is critical for achieving precision, reliability, and efficiency. Among the most popular options are PT100 sensors, thermocouples