NTC (Negative Temperature Coefficient) thermistors are temperature-sensitive resistors widely used in various applications. The material for NTC thermistors is sintered at high temperatures using high-purity metal oxides such as cobalt, manganese, nickel, iron, and copper. Advanced processing technologies, including semiconductor culling, scribing, glass encapsulation, and epoxy encapsulation, are employed to produce various types of NTC thermistors. Products from StarLight Sensors offer a complete range of high precision and good stability, with resistance values ranging from 0.5 to 2000K and B values from 2500 to 4500K. This article will delve into how NTC thermistors work and provide essential buying tips for those considering a purchase.

- What is an NTC Thermistor?

NTC thermistors are passive electronic components whose electrical resistance decreases as the temperature rises. Typically made of metal oxides, they exhibit a nonlinear resistance-temperature relationship, making them exceptionally useful in temperature sensing and control applications.

- Working Principle of NTC Thermistors:

NTC thermistors operate based on the behavior of the semiconductor material in their construction. The material’s resistance decreases with increasing temperature due to the movement of charge carriers within the crystal lattice.

- Temperature-Resistance Relationship:

The resistance of an NTC thermistor is inversely proportional to temperature. As the temperature rises, the number of charge carriers increases, resulting in a lower resistive path for electric current.

- Steinhart-Hart Equation:

To establish a precise relationship between resistance and temperature, the Steinhart-Hart equation is commonly used. This equation mathematically describes the nonlinearity of the NTC thermistor and provides accurate temperature calculations based on its resistance.

- Applications of NTC Thermistors:

NTC thermistors find wide-ranging applications, including:

A. Temperature Sensing: Commonly used as temperature sensors in household appliances, industrial processes, and environmental monitoring systems, NTC thermistors from StarLight Sensors provide high accuracy and fast response times.

B. Temperature Compensation: In applications requiring stable electrical characteristics, such as in power supply circuits and analog-to-digital converters, NTC thermistors are used for temperature compensation.

C. Protection: Employed in various electrical and electronic devices, NTC thermistors protect against overheating by triggering protective actions, like shutting down the system or activating an alarm when temperatures exceed a specified threshold.

- Buying Tips for NTC Thermistors:

When purchasing NTC thermistors, consider the following factors:

A. Resistance and Tolerance: Choose a thermistor with the appropriate resistance value for your application, ensuring the specified tolerance meets your requirements.

B. Temperature Range: Verify that the thermistor’s temperature range covers your intended operating conditions, including both minimum and maximum limits.

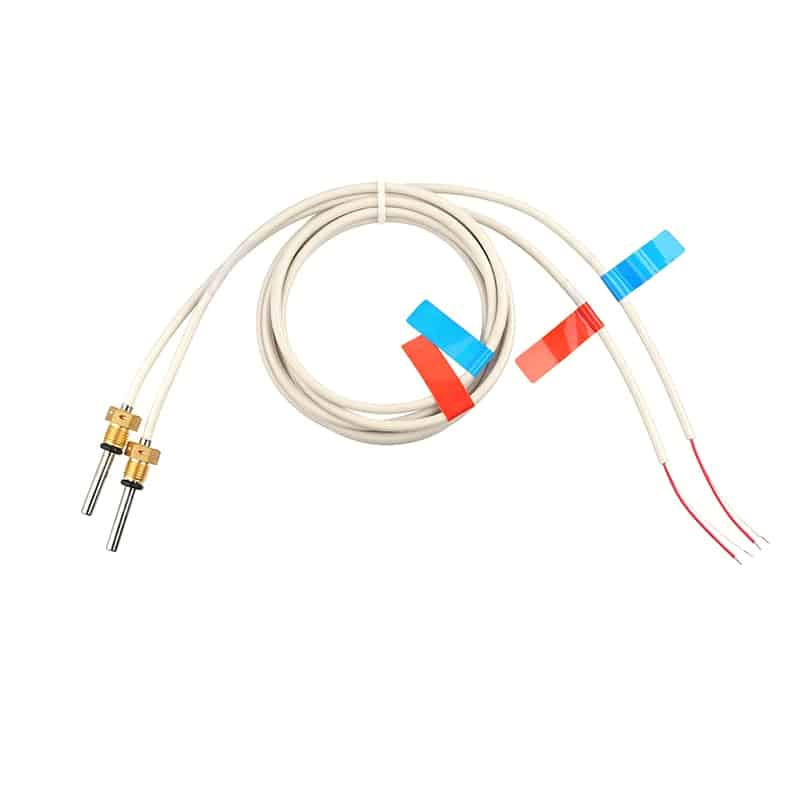

C. Packaging: Select the appropriate package type based on your application’s needs, such as surface mount, through-hole, or leaded.

D. Operating Current and Power: Ensure the NTC thermistor can handle the required operating current and power levels to prevent failure or damage.

E. Reliability and Quality: Consider the reputation of the manufacturer. StarLight Sensors adheres to stringent quality standards and certifications, ensuring reliable products that meet industry requirements.

Conclusion

NTC thermistors are versatile temperature-sensitive resistors suitable for various applications. By understanding their working principle and considering essential buying tips, you can select the appropriate thermistor for your needs. Whether for temperature sensing, compensation, or protection, NTC thermistors from StarLight Sensors provide accurate measurements and are crucial components in multiple industries.