Thermocouples are essential tools in high-temperature industrial applications, providing accurate temperature measurements critical for process control and safety. However, their lifespan can be significantly affected by harsh operating conditions. This article explores strategies to extend the lifespan of thermocouples in high-temperature environments, supported by industry case studies and insights.

Understanding Thermocouple Degradation Mechanisms

Thermocouples operate based on the Seebeck effect, where two dissimilar metals produce a voltage proportional to temperature differences. In high-temperature settings, several degradation mechanisms can impair their performance:

-

Oxidation and Corrosion: Exposure to oxidizing atmospheres can deteriorate thermocouple materials, leading to measurement inaccuracies.

-

Drift: Prolonged exposure to elevated temperatures can cause changes in the thermoelectric properties of thermocouple materials, resulting in signal drift.

-

Mechanical Stress: Thermal expansion mismatches among thermocouple components can induce mechanical stresses, potentially leading to structural failures.

Case Study: Noble-Metal Thermocouple Stability

A study by the National Bureau of Standards (now NIST) investigated the stability of noble-metal thermocouples at high temperatures. The research highlighted that thermocouples made from platinum and rhodium alloys exhibited better stability and longer lifespans in high-temperature environments compared to base-metal thermocouples. This underscores the importance of material selection in extending thermocouple lifespan.

Strategies for Extending Thermocouple Lifespan

-

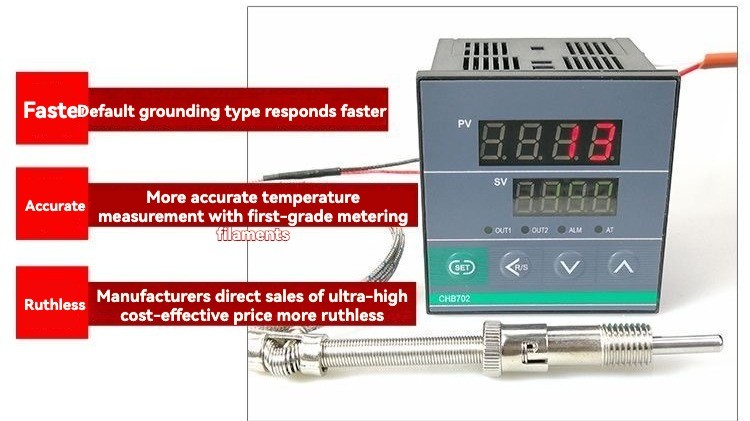

Material Selection: Choosing appropriate thermocouple materials is crucial. Noble-metal thermocouples, such as Type S (platinum-rhodium), offer superior stability at high temperatures but come at a higher cost. Base-metal thermocouples, like Type K (nickel-chromium/nickel-aluminum), are more economical but may have shorter lifespans in extreme conditions.

-

Protective Sheathing: Utilizing protective sheaths made from materials like high-temperature alloys or ceramics can shield thermocouples from corrosive environments, reducing oxidation and mechanical damage.

-

Calibration and Maintenance: Regular calibration ensures measurement accuracy. Implementing maintenance schedules to inspect and replace degraded thermocouples can prevent unexpected failures.

-

Environmental Control: Minimizing exposure to corrosive gases and controlling the ambient atmosphere can significantly reduce oxidation and other degradation processes.

-

Advanced Sensor Technologies: Emerging sensor technologies, such as high-temperature irradiation-resistant thermocouples (HTIR-TCs), have shown promise in maintaining stability under extreme conditions. Research indicates that HTIR-TCs can operate with minimal drift over extended periods at high temperatures.

Conclusion

Extending the lifespan of thermocouples in high-temperature environments requires a comprehensive approach that includes selecting appropriate materials, employing protective measures, maintaining regular calibration, and exploring advanced sensor technologies. By understanding and mitigating degradation mechanisms, industries can enhance the reliability and accuracy of temperature measurements, leading to improved process efficiency and safety.