When selecting a thermocouple for temperature measurement, two of the most common choices are Type K and Type J. Both have distinct advantages and limitations depending on the environment and specific industrial applications. Understanding their differences is essential to choosing the right thermocouple for your needs.

This article provides a detailed comparison of Type K and Type J thermocouples, including real-world case studies, industry-specific applications, and expert insights.

1. Overview of Thermocouples and Their Importance

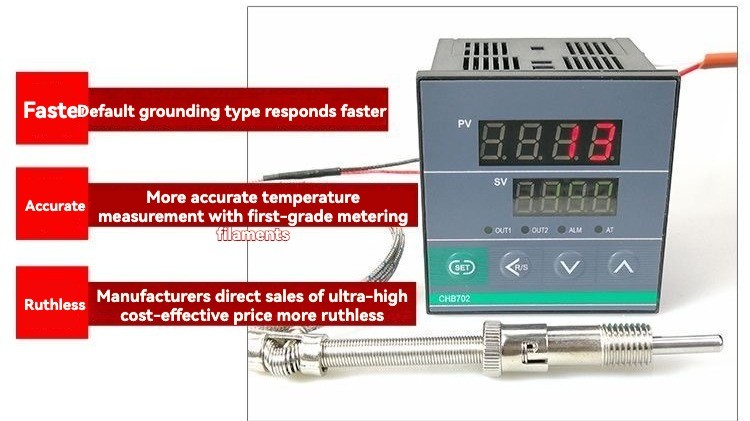

Thermocouples are widely used temperature sensors that measure heat based on the Seebeck effect—when two different metals generate voltage corresponding to temperature. They are highly valued for their durability, cost-effectiveness, and rapid response time, making them essential in industries like manufacturing, HVAC, food processing, and aerospace.

Among the various thermocouple types, Type K and Type J stand out for their reliability and versatility. However, selecting the wrong type can lead to measurement errors, premature sensor failure, and operational inefficiencies.

2. What is a Type K Thermocouple?

Composition and Characteristics

- Metals used: Nickel-Chromium (positive leg) and Nickel-Alumel (negative leg).

- Temperature range: -200°C to 1,260°C (-328°F to 2,300°F).

- Accuracy: ±2.2°C or ±0.75% of reading.

- Durability: Highly resistant to oxidation.

- Sensitivity: 41 µV/°C.

Advantages of Type K

✔ High-temperature range: Suitable for extreme heat applications. ✔ Oxidation resistance: Performs well in oxidizing atmospheres. ✔ Wide industry acceptance: Standard choice for aerospace, power generation, and metal processing. ✔ Good longevity: Can withstand harsh conditions for extended periods.

Limitations of Type K

✖ Susceptible to corrosion in reducing atmospheres (e.g., hydrogen or vacuum conditions). ✖ Prone to drift over time in high-temperature environments.

Common Applications

✅ Gas turbines ✅ Heat treatment furnaces ✅ Boilers and kilns ✅ Chemical processing ✅ Exhaust temperature monitoring

Case Study: Type K Thermocouple in Aerospace

A leading aerospace manufacturer required accurate temperature monitoring for jet engine components operating at 1,100°C (2,012°F). They selected Type K thermocouples for their high-temperature resilience and oxidation resistance, ensuring precise thermal control in fuel combustion systems and turbine blades.

3. What is a Type J Thermocouple?

Composition and Characteristics

- Metals used: Iron (positive leg) and Constantan (negative leg).

- Temperature range: -40°C to 750°C (-40°F to 1,382°F).

- Accuracy: ±2.2°C or ±0.75% of reading.

- Durability: Vulnerable to oxidation at high temperatures.

- Sensitivity: 50 µV/°C.

Advantages of Type J

✔ More affordable than Type K – cost-effective solution for lower temperatures. ✔ Higher sensitivity (50 µV/°C) – provides better signal response at moderate temperatures. ✔ Works well in reducing atmospheres, unlike Type K. ✔ Common in industrial and food processing applications due to lower temperature needs.

Limitations of Type J

✖ Shorter lifespan in oxidizing environments – iron wire degrades over time. ✖ Lower temperature range – not suitable for extreme heat conditions.

Common Applications

✅ Injection molding ✅ Food processing equipment ✅ Ovens and dryers ✅ Laboratory temperature measurement ✅ Oil and gas refining

Case Study: Type J in Food Processing

A commercial bakery needed precise temperature control for its ovens (400°C/752°F) to ensure uniform baking. Since their application didn’t require high-temperature tolerance, Type J thermocouples were the best fit, offering cost efficiency and rapid temperature response.

4. Direct Comparison: Type K vs. Type J

FeatureType K ThermocoupleType J ThermocoupleTemperature Range-200°C to 1,260°C-40°C to 750°CBest Use CasesHigh-temperature and oxidizing environmentsLower-temperature applicationsAccuracy±2.2°C or ±0.75%±2.2°C or ±0.75%Sensitivity41 µV/°C50 µV/°CDurabilityHighly resistant to oxidationProne to oxidation (iron wire)CostSlightly more expensiveMore affordable

5. How to Choose the Right Thermocouple for Your Application?

When deciding between Type K and Type J, consider the following factors:

1. Temperature Requirements

- If your application requires temperatures above 750°C, Type K is the only choice.

- For lower temperatures, Type J may be more cost-effective.

2. Environmental Conditions

- Type K excels in oxidizing environments but fails in reducing atmospheres.

- Type J is ideal for reducing atmospheres but deteriorates in oxidation.

3. Industry-Specific Needs

- Manufacturing and metal processing? → Type K.

- Food industry and HVAC systems? → Type J.

4. Cost Considerations

- If budget constraints exist and temperatures don’t exceed 750°C, Type J offers better value.

5. Longevity & Maintenance

- Type K lasts longer in harsh conditions.

- Type J requires frequent replacements in oxidizing settings.

6. Industry-Specific Recommendations

IndustryRecommended ThermocoupleReasonAerospaceType KHigh-temperature resilienceFood ProcessingType JCost-effective for moderate temperaturesMetalworkingType KPerforms well in extreme heatOil & GasType KWithstands harsh environmentsPlastic ManufacturingType JSuitable for molding processesPower PlantsType KLong lifespan in high-heat conditions

7. Conclusion: Which is Better for You?

Both Type K and Type J thermocouples have their strengths and weaknesses. The best choice depends on temperature range, environmental conditions, industry applications, and cost considerations.

Final Recommendations:

- Choose Type K for high temperatures, long-term reliability, and oxidizing atmospheres.

- Opt for Type J when working below 750°C in a cost-sensitive, reducing atmosphere environment.

By selecting the right thermocouple, you ensure accurate temperature readings, increased efficiency, and longer equipment life—a crucial factor for optimizing industrial operations.

Still unsure? Contact a temperature control expert to determine the most suitable thermocouple for your application.