Dual Thermocouple: Enhancing Precision and Accuracy in Temperature Measurement

Abstract:

In this article, we will explore the fascinating technology of dual thermocouples and how they play a crucial role in achieving precise and accurate temperature measurements. We will delve into the working principles, applications, advantages, and tips for optimizing the use of dual thermocouples in various industries. Whether you are a scientist, engineer, or simply curious about temperature measurement, this comprehensive guide will equip you with the knowledge to harness the power of dual thermocouples effectively.

Table of Contents:

1. Introduction

2. Understanding Thermocouples

3. The Dual Thermocouple Advantage

4. Applications of Dual Thermocouples

4.1 Industrial Sector

4.2 Research and Development

4.3 HVAC Systems

4.4 Food Processing Industry

5. Optimizing Dual Thermocouple Performance

5.1 Proper Calibration and Maintenance

5.2 Correct Placement and Wiring

5.3 Shielding from Interference

5.4 Consideration of Cold Junction Compensation

6. Conclusion

1. Introduction

Temperature measurement is a critical aspect of numerous industries, ranging from manufacturing processes to scientific research. Accurate temperature readings ensure the safety, quality, and efficiency of operations. In this digital era, thermocouples have emerged as a reliable and cost-effective solution for temperature sensing. Amongst various types, the dual thermocouple stands out, providing unparalleled precision and accuracy. Let’s delve deeper into the world of dual thermocouples and uncover their remarkable capabilities.

2. Understanding Thermocouples

Before we dive into the specifics of dual thermocouples, let’s first understand the basic principles behind thermocouples. A thermocouple consists of two dissimilar metals joined at one end, forming a junction. When a temperature difference exists between the junction and the other end of the metals, it generates a voltage that is proportional to the temperature gradient. This phenomenon is known as the Seebeck effect.

3. The Dual Thermocouple Advantage

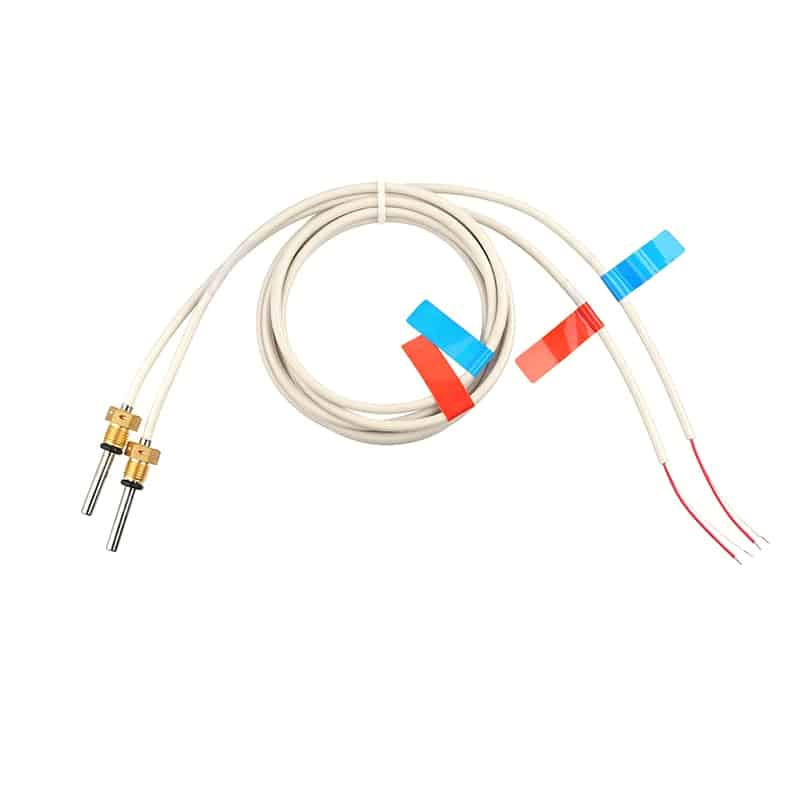

Dual thermocouples, as the name suggests, utilize two sets of thermocouples within a single probe. This design offers several advantages over traditional single thermocouples. Firstly, dual thermocouples provide redundancy, ensuring accurate temperature readings even if one set of thermocouples fails. Secondly, they enhance precision by averaging the measurements from both sets, reducing the impact of localized temperature fluctuations. Lastly, dual thermocouples enable continuous monitoring of multiple points using a single probe, optimizing efficiency and cost-effectiveness.

4. Applications of Dual Thermocouples

4.1 Industrial Sector

In industries such as petrochemicals, power generation, and metal fabrication, precise temperature control is crucial. Dual thermocouples find widespread usage in these sectors to monitor reactors, furnaces, and various process equipment. The redundancy provided by dual thermocouples ensures reliable operation and minimizes the risk of costly shutdowns due to inaccurate temperature measurements.

4.2 Research and Development

Scientists and researchers rely on accurate temperature measurements for experiments, material testing, and environmental simulations. Dual thermocouples offer precise and consistent data, enabling them to make informed decisions and draw reliable conclusions. From materials science to pharmaceutical research, the versatility of dual thermocouples proves invaluable.

4.3 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems require precise temperature monitoring to maintain optimal comfort and energy efficiency. Dual thermocouples are often employed in these systems to measure both the air temperature and the temperature of heating/cooling coils. This data allows for efficient control of HVAC operations, resulting in improved energy savings and prolonged equipment lifespan.

4.4 Food Processing Industry

Temperature control plays a vital role in ensuring food safety and quality. Dual thermocouples find wide application in food processing equipment, ranging from ovens to refrigeration units. By closely monitoring the temperature at critical points, such as cooking chambers or cold storage compartments, dual thermocouples help prevent bacterial growth, maintain product quality, and comply with regulatory standards.

5. Optimizing Dual Thermocouple Performance

To maximize the benefits of dual thermocouples, certain optimization techniques should be implemented.

5.1 Proper Calibration and Maintenance

Regular calibration and maintenance are essential to ensure accurate temperature readings. Calibration checks should be conducted periodically, and any drift or deviation should be addressed promptly. Thorough cleaning of the probe and regular inspections also contribute to optimal performance.

5.2 Correct Placement and Wiring

Proper placement and wiring of dual thermocouples are crucial for accurate measurements. The probe should be positioned as close as possible to the target area, minimizing thermal lag. Additionally, care should be taken to avoid electromagnetic interference by routing the wiring away from potential noise sources.

5.3 Shielding from Interference

Dual thermocouples may be susceptible to interference from external factors such as electromagnetic fields or radiofrequency signals. Utilizing suitable shielding techniques, such as grounded metal enclosures or twisted pair cables, can effectively mitigate these interferences and ensure reliable temperature measurements.

5.4 Consideration of Cold Junction Compensation

To account for the reference temperature at the measurement junction, cold junction compensation is necessary. This correction allows for accurate temperature calculations by compensating for the temperature difference between the measurement junction and the reference junction. Implementing dedicated cold junction compensation techniques or utilizing specialized dual thermocouples with built-in compensation circuits can enhance accuracy.

6. Conclusion

Dual thermocouples offer an exceptional solution for precise and accurate temperature measurement across various industries. Their redundancy, averaging capability, and multiple-point monitoring make them a preferred choice for critical applications. By understanding their working principles, optimizing their performance, and adhering to proper calibration and maintenance practices, you can harness the full potential of dual thermocouples and elevate temperature measurement accuracy to new heights.

Discovering the Range of Temperature Sensors from Leading PT Sensors Manufacturer

Platinum resistance temperature sensors from reliable suppliers offer precise measurements with tolerances within tenths of a degree Celsius and withstand pressures up to sixteen bar.