Fluke 805 ES External Vibration Sensor – Measure Vibration with Precision

Table of Contents

- Introduction

- The Fluke 805 ES External Vibration Sensor

- Applications for the Fluke 805 ES

- Key Features of the Fluke 805 ES

- Conclusion

Introduction

Welcome to our comprehensive guide on the Fluke 805 ES External Vibration Sensor. In this article, we will explore how this innovative sensor can help you accurately measure vibration levels and diagnose potential issues in various applications.

The Fluke 805 ES External Vibration Sensor

The Fluke 805 ES External Vibration Sensor is a cutting-edge device designed to provide precise vibration measurements in a wide range of industrial settings. It is engineered with advanced technology to ensure accurate readings and help maintenance professionals identify potential faults before they lead to costly machinery breakdowns.

Applications for the Fluke 805 ES

The Fluke 805 ES External Vibration Sensor finds applications in numerous industries, including:

- Manufacturing

- Energy

- Transportation

- Oil and gas

- Food processing

With its versatile design and durable construction, it can be used for a wide range of equipment, such as motors, pumps, compressors, fans, and more.

Key Features of the Fluke 805 ES

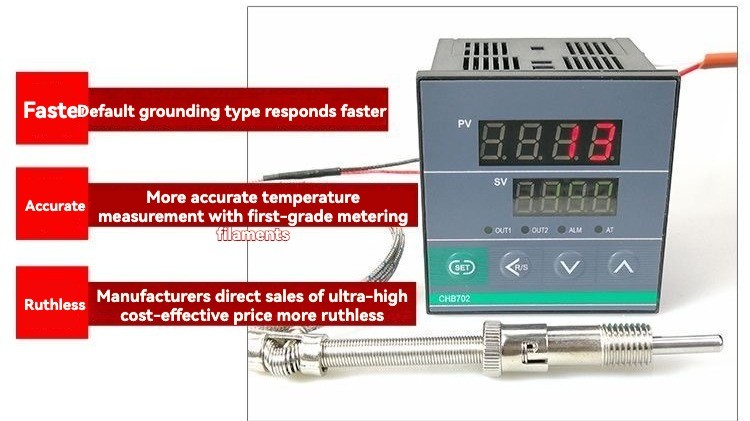

The Fluke 805 ES offers several key features that make it an invaluable tool for vibration analysis:

- External sensor: The sensor can be easily attached to the machinery, allowing for accurate readings without the need for disassembly.

- Highly sensitive: It can detect even the slightest vibrations, enabling early detection of potential issues.

- Data logging capability: The sensor can store vibration data for further analysis and comparison.

- Portable and user-friendly: With its compact size and intuitive interface, the Fluke 805 ES is easy to use in various conditions.

Conclusion

The Fluke 805 ES External Vibration Sensor is a reliable and efficient tool for measuring vibration in industrial environments. Its precision, durability, and user-friendly design make it an ideal choice for maintenance professionals. By detecting and addressing vibration-related issues early on, businesses can save time, money, and prevent costly machinery failures.