Fluke Vibration Sensor – Improve Your Machine Health Monitoring

Abstract

This article explores the benefits and features of Fluke vibration sensors for machine health monitoring. Discover how these sensors can help businesses enhance equipment maintenance, reduce downtime, and improve overall productivity.

Table of Contents

- Introduction

- The Importance of Machine Health Monitoring

- Introducing Fluke Vibration Sensors

- Key Features and Benefits

- Conclusion

Introduction

In today’s industrial landscape, maintaining the health of machines and equipment is crucial for efficient operations and cost savings. Machine failures and downtime can result in substantial financial losses. To address this challenge, Fluke Corporation offers innovative vibration sensors designed to detect and monitor machine vibrations accurately.

The Importance of Machine Health Monitoring

Machine health monitoring plays a vital role in predictive maintenance strategies. By continuously monitoring vibrations, businesses can identify potential issues before they escalate into major problems. This proactive approach helps prevent unplanned breakdowns, minimizes repair costs, and extends the lifespan of critical equipment.

With Fluke vibration sensors, companies gain real-time insights into the condition of their machines. This information allows them to schedule maintenance activities strategically, avoiding costly production interruptions and ensuring optimal operational efficiency.

Introducing Fluke Vibration Sensors

Fluke vibration sensors are advanced devices that utilize cutting-edge technology to measure and analyze machine vibrations accurately. These compact sensors can be easily installed on various types of equipment, including motors, pumps, compressors, and rotating machinery.

Fluke sensors capture vibration data in multiple axes, providing comprehensive insights into machine performance. They offer reliable and precise measurements, enabling users to identify abnormal vibrations and take appropriate actions promptly.

Key Features and Benefits

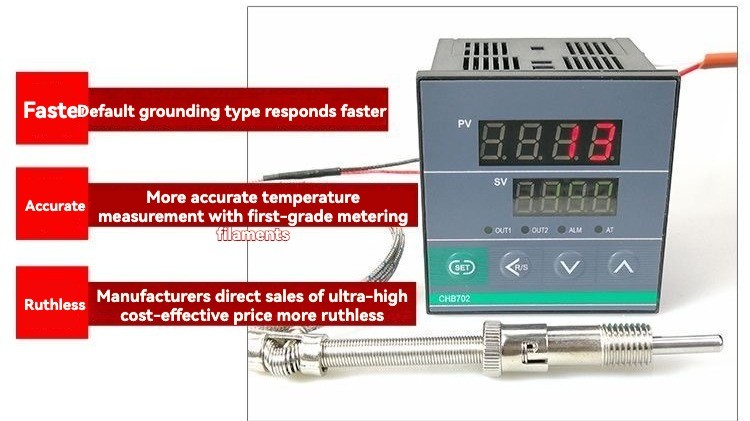

Fluke vibration sensors are equipped with several essential features that make them indispensable for effective machine health monitoring:

- High Accuracy: Fluke sensors provide precise vibration measurements, enabling early detection of potential faults.

- Wireless Connectivity: The sensors transmit data wirelessly, allowing convenient remote monitoring and analysis.

- Real-Time Alerts: Fluke sensors can send automated alerts when abnormal vibrations or fault conditions are detected, ensuring prompt attention and action.

- Data Logging: These sensors can store vibration data, enabling historical analysis for trend identification and predictive maintenance planning.

- Easy Installation: Fluke vibration sensors are user-friendly and can be quickly installed without requiring extensive technical expertise.

By leveraging these features, businesses can experience several benefits:

- Reduced Downtime: Early fault detection and timely maintenance significantly reduce unplanned downtime and associated losses.

- Cost Savings: Preventing catastrophic machine failures through proactive maintenance helps minimize repair costs and extends equipment lifespan.

- Improved Productivity: By ensuring optimal machine performance, Fluke sensors contribute to enhanced overall productivity and operational efficiency.

Conclusion

Fluke vibration sensors are powerful tools that enable businesses to enhance machine health monitoring and implement effective predictive maintenance strategies. By leveraging the accuracy and real-time insights provided by these sensors, companies can proactively address issues, minimize downtime, and optimize their equipment’s performance. Start integrating Fluke vibration sensors into your maintenance program and experience the benefits of improved machine health monitoring today!