Gas Temperature Sensor: How It Works and Its Importance

Abstract

- Introduction

- Understanding Gas Temperature Sensors

- Applications of Gas Temperature Sensors

- Choosing the Right Gas Temperature Sensor

- Installation and Maintenance Tips

- Conclusion

Introduction

Gas temperature sensors play a crucial role in various industries, enabling accurate measurements and monitoring of temperature variations in gas-filled environments. In this article, we will explore the functionality, applications, and tips for choosing and maintaining gas temperature sensors.

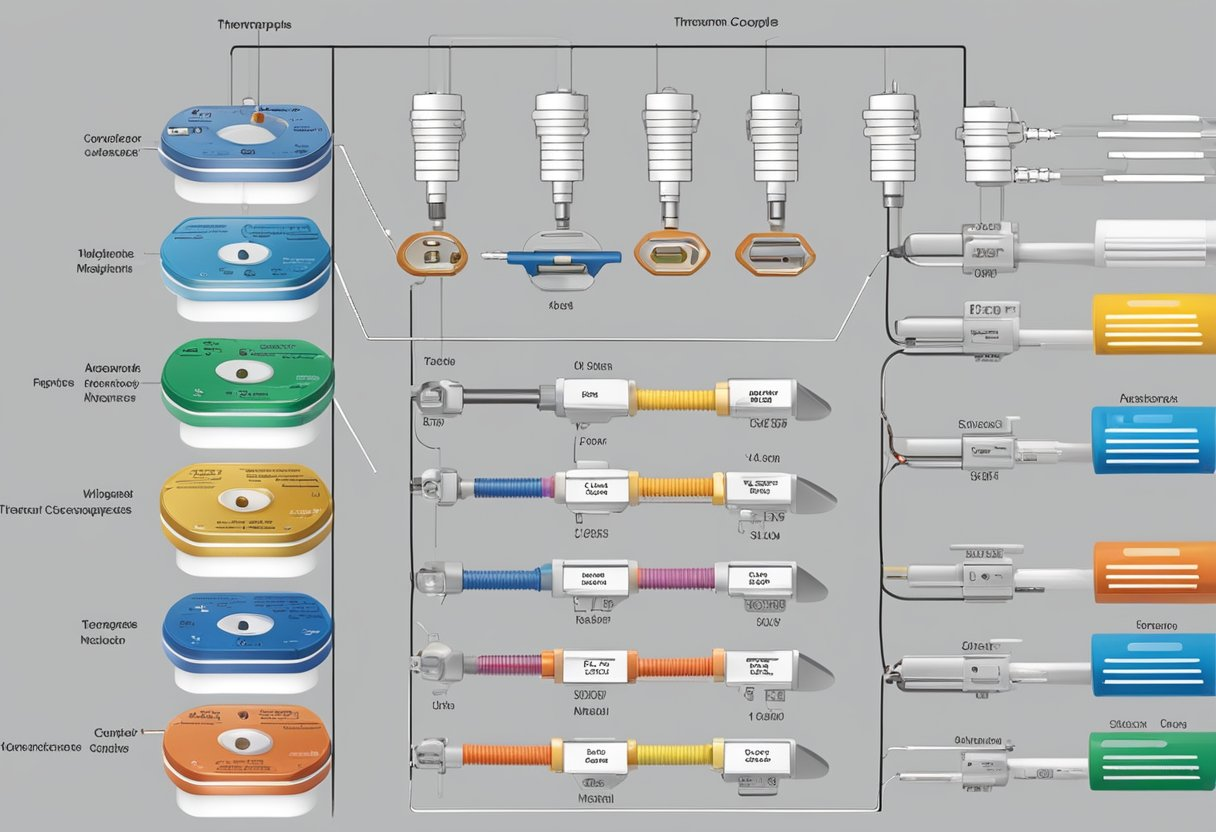

Understanding Gas Temperature Sensors

Gas temperature sensors are electronic devices designed to measure and monitor the temperature of gases. They employ various technologies, such as thermocouples, resistance temperature detectors (RTDs), and infrared sensors, to detect thermal changes in gas environments.

These sensors are typically equipped with a temperature-sensitive element that converts temperature variations into electrical signals. The signals are then processed and displayed in a readable format for analysis and control purposes.

Applications of Gas Temperature Sensors

Gas temperature sensors find applications in a wide range of industries, including:

- Oil and gas: Monitoring temperature in pipelines and refineries

- Automotive: Measuring exhaust gas temperatures

- Environmental monitoring: Analyzing air temperature in pollution control systems

- Industrial processes: Optimizing temperature control for chemical reactions

- Power generation: Ensuring efficient operation of gas turbines

Choosing the Right Gas Temperature Sensor

When selecting a gas temperature sensor, several factors should be considered:

- Temperature range: Ensure the sensor is compatible with the specific temperature range required for your application.

- Accuracy: Look for sensors with high accuracy to ensure precise temperature measurements.

- Response time: Consider the response time required for your application, as some sensors may provide faster readings than others.

- Environmental conditions: Evaluate the environmental conditions, such as humidity and pressure, to choose a sensor that can withstand the operating environment.

- Cost: Balance the cost of the sensor with the required performance and features.

Installation and Maintenance Tips

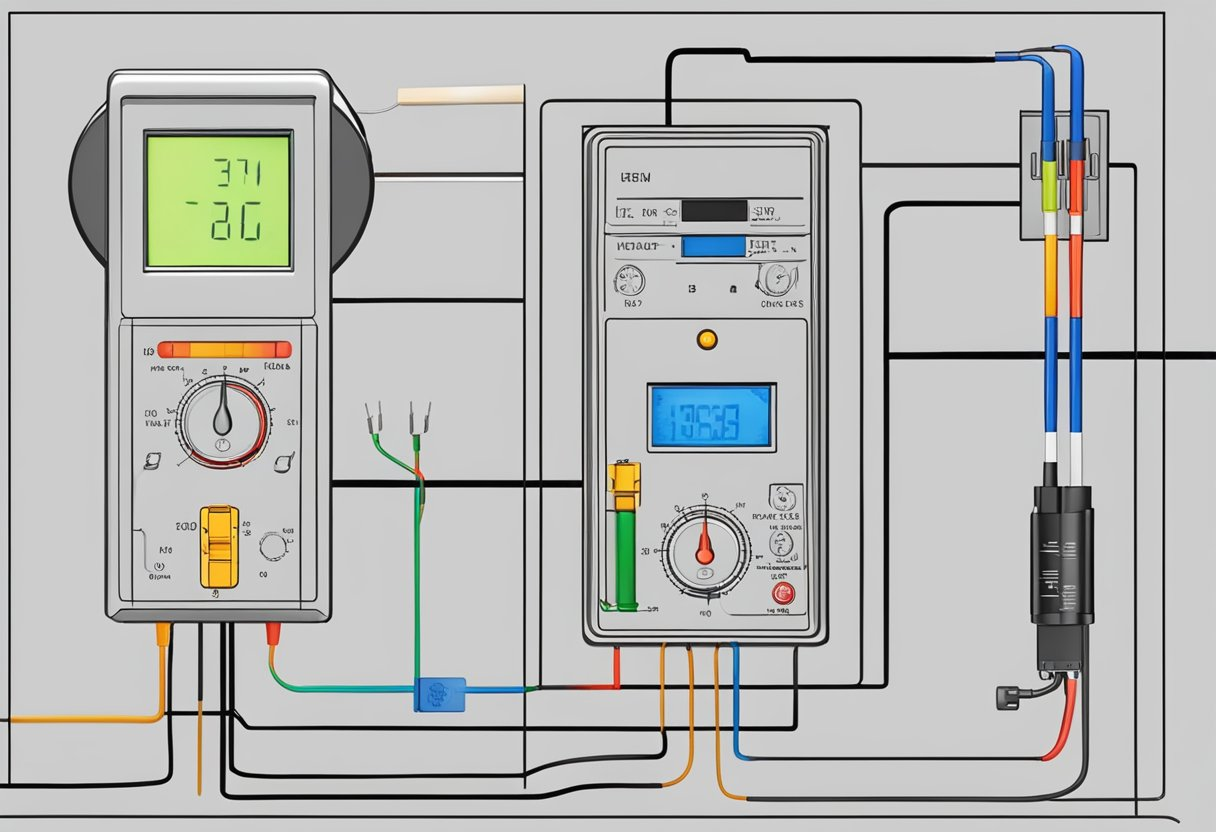

Proper installation and maintenance are essential for optimal sensor performance:

- Ensure correct sensor placement to measure the target gas temperature accurately.

- Periodically calibrate the sensor to maintain measurement accuracy.

- Regularly clean the sensor to prevent dust or debris buildup that can affect its functionality.

- Follow manufacturer guidelines for storage and handling of the sensor.

- Monitor sensor performance regularly and replace if any signs of degradation are observed.

Conclusion

Gas temperature sensors are vital tools for accurate temperature monitoring in various industries. Understanding their functionality, choosing the right sensor, and properly maintaining it can contribute to efficient operations and improved safety. By considering the factors mentioned in this article, you can make informed decisions regarding gas temperature sensors for your specific application.