Discover the Benefits of Intrinsically Safe Thermometers

Article Summary

Introduction

In today’s industries, safety is of paramount importance. When it comes to measuring temperature in hazardous

environments, such as oil refineries or chemical plants, using intrinsically safe thermometers becomes

crucial. These specialized instruments are designed to prevent any potential ignition source that could

cause an explosion or fire in volatile surroundings.

Benefits of Intrinsically Safe Thermometers

Intrinsically safe thermometers offer several advantages over their conventional counterparts:

- Enhanced Safety: The primary benefit of intrinsically safe thermometers is their ability to operate safely

in hazardous areas where flammable gases, liquids, or dust may be present. By eliminating the risk of

sparks or excessive heat, these devices provide a higher level of safety for both personnel and the

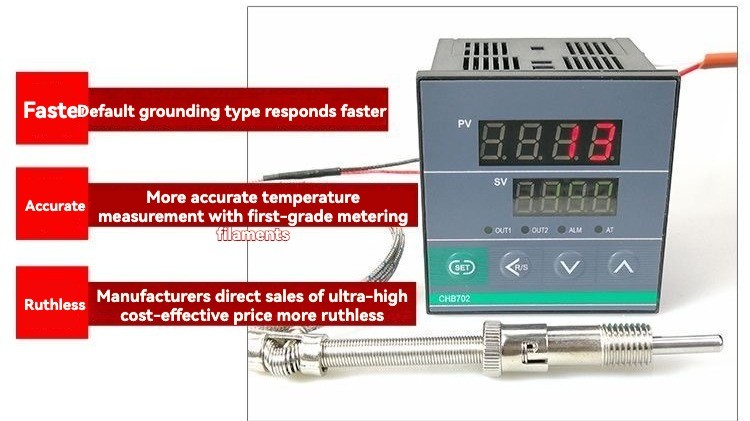

surrounding environment. - Accurate Measurements: Despite their safety features, intrinsically safe thermometers still deliver precise

temperature readings. Their advanced technology ensures accuracy, allowing operators to monitor critical

processes with confidence. - Durable Construction: Intrinsically safe thermometers are built to withstand harsh conditions. They are

typically resistant to water, dust, extreme temperatures, and mechanical shocks, ensuring reliable

performance even in challenging industrial settings. - Ease of Use: These thermometers are designed with user-friendly interfaces, making them easy to operate for

technicians, engineers, and other professionals. They often have clear displays, intuitive controls, and

may offer additional features like data logging or wireless connectivity.

Applications of Intrinsically Safe Thermometers

Intrinsically safe thermometers find extensive use in various industries and scenarios:

- Oil and Gas: From offshore drilling platforms to refinery operations, intrinsically safe thermometers play a

crucial role in monitoring temperatures to ensure safe and efficient processes in this volatile industry. - Chemical Manufacturing: Chemical plants dealing with flammable substances require precise temperature

measurement. Intrinsically safe thermometers provide accurate data without compromising safety. - Mining: Hazardous mining environments demand intrinsically safe instruments for temperature monitoring to

prevent potential accidents or explosions. - Pharmaceuticals: In pharmaceutical production facilities, where strict safety regulations are paramount,

intrinsically safe thermometers maintain compliance while ensuring accurate temperature control.

Conclusion

Intrinsically safe thermometers are essential tools for industries operating in hazardous environments. Their

ability to provide accurate temperature measurements without posing any risks is invaluable. Whether it’s in

oil and gas, chemical manufacturing, mining, or pharmaceuticals, these instruments enhance safety and

efficiency in critical processes. Invest in intrinsically safe thermometers to protect your workforce and

assets while maintaining optimal productivity.