k type temperature sensor – A Comprehensive Guide to Temperature Sensing Technology

Article Summary:

- Introduction

- Benefits of K Type Temperature Sensors

- Applications in Various Industries

- Factors to Consider When Selecting a K Type Temperature Sensor

- Tips for Maintenance and Care

- Conclusion

Introduction

Temperature sensing technology has revolutionized numerous industries, and the K type temperature sensor has played a pivotal role in this transformation. As a crucial component in measuring temperature, K type sensors offer unparalleled accuracy and reliability. In this comprehensive guide, we will delve into the intricacies of K type temperature sensors, exploring their benefits, applications, selection criteria, and maintenance tips.

Benefits of K Type Temperature Sensors

One of the standout advantages of K type temperature sensors is their wide temperature measurement range, which extends from -200°C to +1250°C. This makes them suitable for diverse industrial applications, ranging from manufacturing processes to environmental monitoring. Moreover, their robust design enables them to withstand harsh conditions, ensuring consistent performance in demanding environments.

Applications in Various Industries

K type temperature sensors find extensive use in metallurgy, pharmaceuticals, petrochemicals, and food processing industries. Their versatility and precision make them indispensable for monitoring and controlling temperature in furnaces, ovens, kilns, and various heating processes. Furthermore, they are employed in research laboratories and HVAC systems, showcasing their adaptability across different sectors.

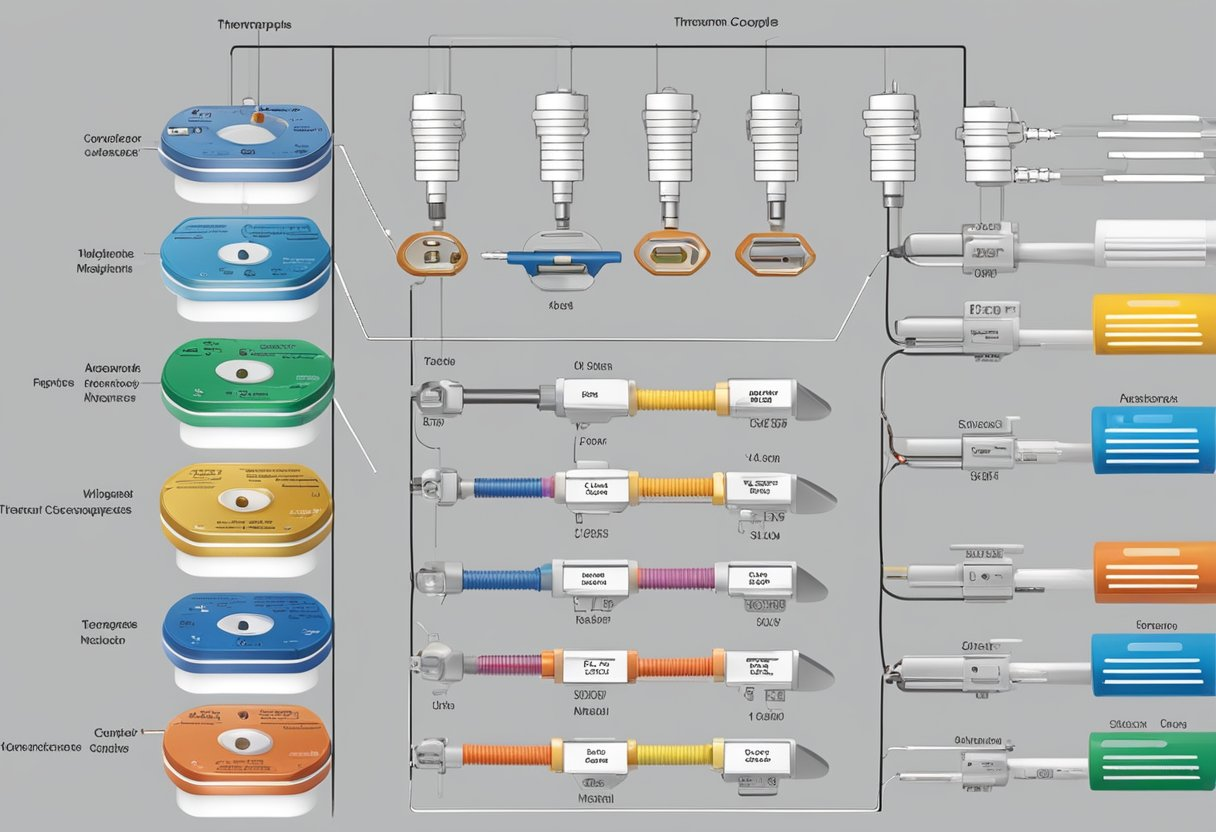

Factors to Consider When Selecting a K Type Temperature Sensor

When choosing a K type temperature sensor, several factors warrant careful consideration. These include the measurement range required for the application, sensor response time, accuracy, and environmental conditions. Additionally, assessing the sensor’s compatibility with the measurement system is essential to ensure seamless integration and optimal performance.

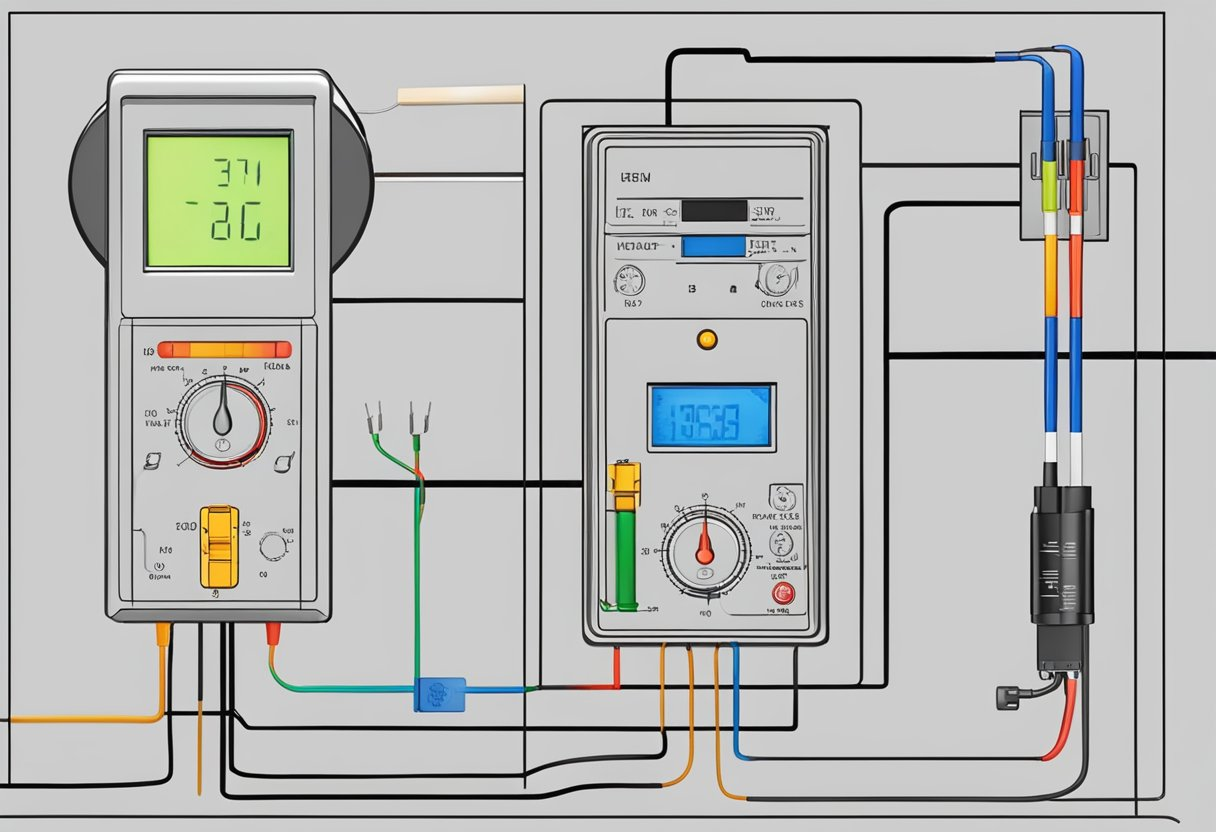

Tips for Maintenance and Care

Proper maintenance is vital to prolonging the lifespan and sustaining the accuracy of K type temperature sensors. Regular calibration, inspection for wear and tear, and adherence to manufacturer guidelines are essential practices. Furthermore, implementing preventive maintenance schedules can preemptively identify issues and mitigate potential sensor failures.

Conclusion

In conclusion, K type temperature sensors stand as stalwarts in the realm of temperature measurement, offering unparalleled benefits, widespread applicability, and critical precision. By understanding the intricacies of these sensors and embracing best practices for their selection and maintenance, industries can harness their full potential for enhanced operational efficiency and quality assurance.