k type thermocouple 1200 c: A Comprehensive Guide

Table of Contents

- Introduction

- Understanding K Type Thermocouples

- Advantages and Disadvantages of K Type Thermocouples

- Applications of K Type Thermocouples

- How to Select and Install K Type Thermocouples

- Conclusion

Introduction

Welcome to our comprehensive guide on k type thermocouple 1200 c, an essential tool used in temperature measurement

applications. In this article, we will explore the benefits, limitations, and various applications of k type

thermocouples, as well as provide insights on how to select and install them effectively.

Understanding K Type Thermocouples

K type thermocouples are widely used in industries due to their reliability and versatility. These thermocouples

consist of two dissimilar metals – chromel and alumel – that generate voltage proportional to the temperature

difference between the measuring junction and the reference junction.

The temperature range of k type thermocouples is impressive, with a maximum limit of 1200 c. They are commonly

employed in high-temperature applications, making them suitable for various industries such as metallurgy,

petrochemical, and heat treatment.

Advantages and Disadvantages of K Type Thermocouples

As with any measurement technology, k type thermocouples come with their own set of advantages and disadvantages.

Let’s take a closer look:

Advantages:

- Wide temperature range, up to 1200 c

- Affordable and readily available

- High accuracy and sensitivity

- Can withstand harsh environments

Disadvantages:

- Limited lifespan

- Non-linear temperature reading

- Requires reference junction compensation

Applications of K Type Thermocouples

K type thermocouples find extensive usage in various industries due to their unique characteristics. Some notable

applications include:

- Heat treatment processes

- Metal and glass manufacturing

- Chemical and petrochemical industries

- Automotive and aerospace sectors

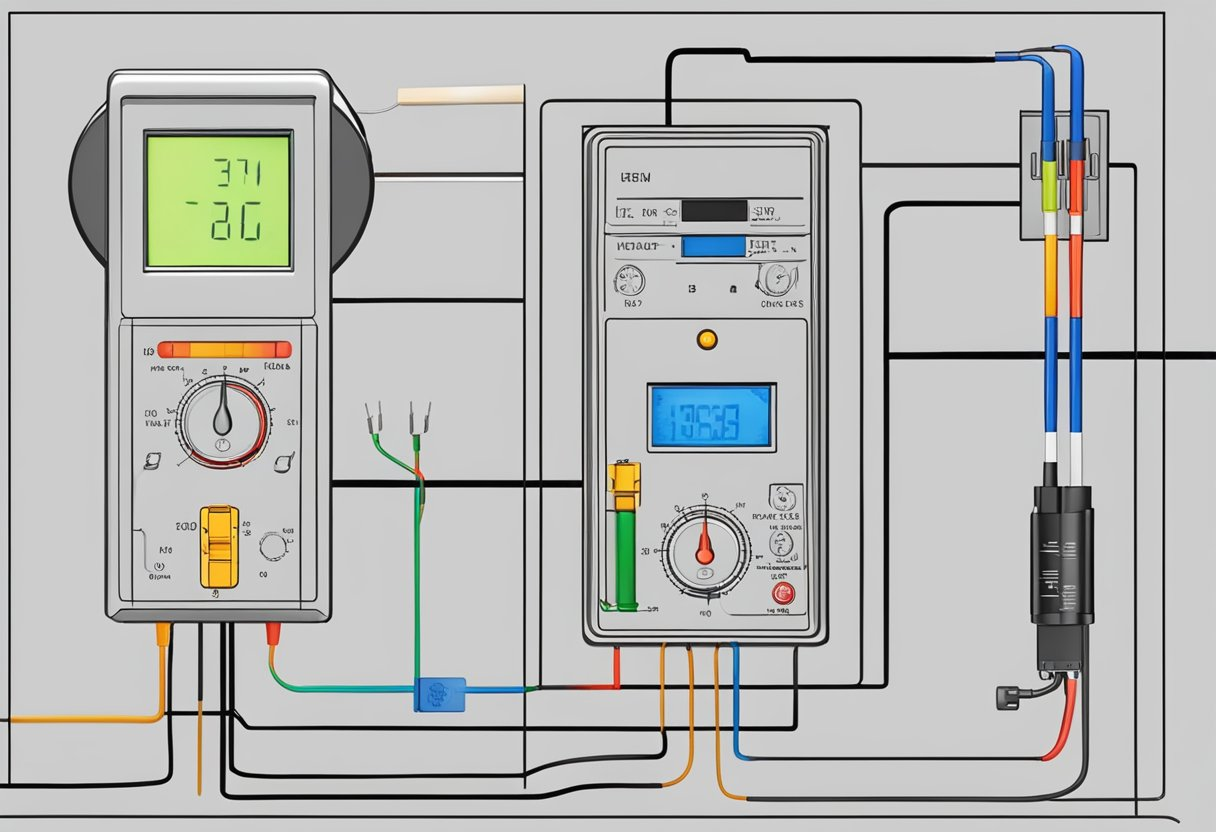

How to Select and Install K Type Thermocouples

Choosing and installing the right k type thermocouple is crucial for accurate temperature measurements. Consider

the following factors:

- Select the appropriate thermocouple grade based on temperature range and environment.

- Consider the accuracy and response time required for your application.

- Ensure proper installation techniques to prevent measurement errors.

- Regularly calibrate and maintain the thermocouples for optimal performance.

Conclusion

K type thermocouples are a reliable and widely used temperature measurement tool, especially in high-temperature

applications. Understanding their advantages, limitations, and proper selection/installation techniques is

crucial for accurate and consistent temperature monitoring. By following the guidelines outlined in this guide,

you can effectively utilize k type thermocouples in your industry and ensure reliable temperature readings.