The platinum resistance temperature sensor measures temperature by using the characteristic that the resistance value of metal platinum changes accordingly when the temperature changes, and the display instrument will indicate the temperature value corresponding to the resistance value of the platinum resistance. When there is a temperature gradient in the measured medium, the measured temperature is the average temperature in the medium layer within the range where the temperature sensing element is located.

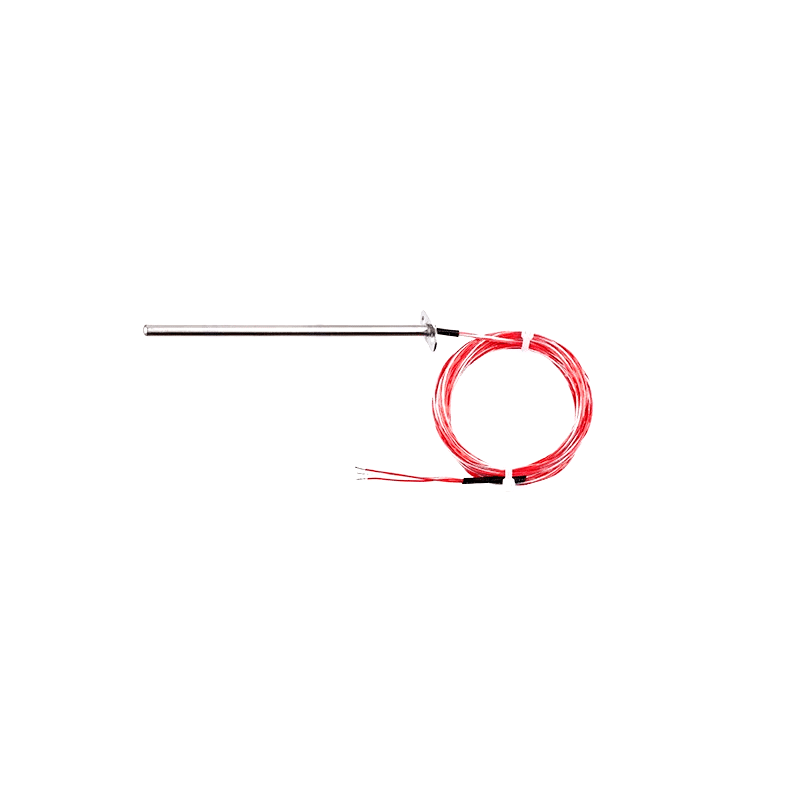

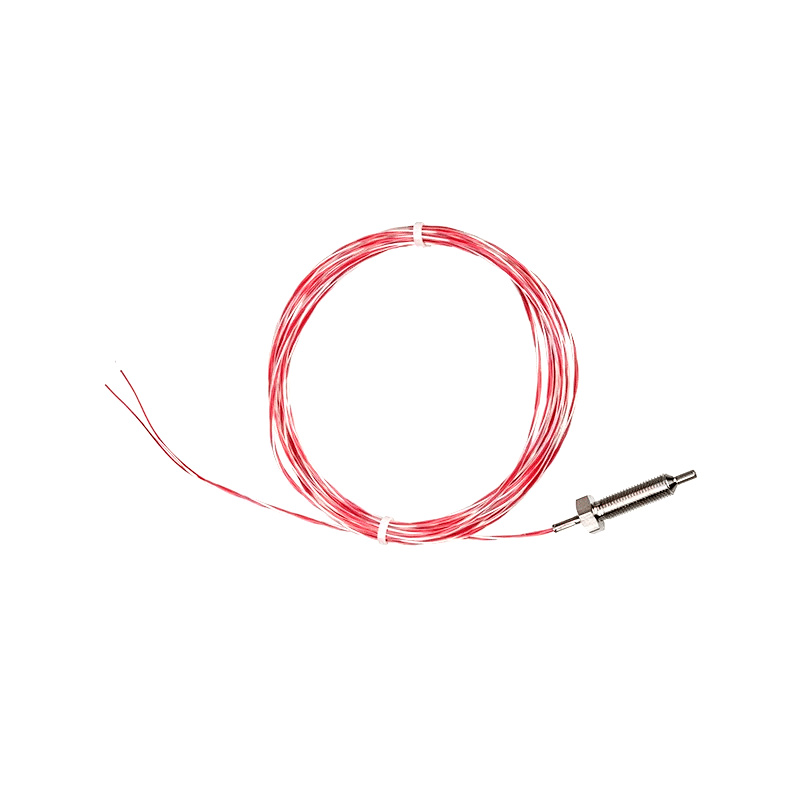

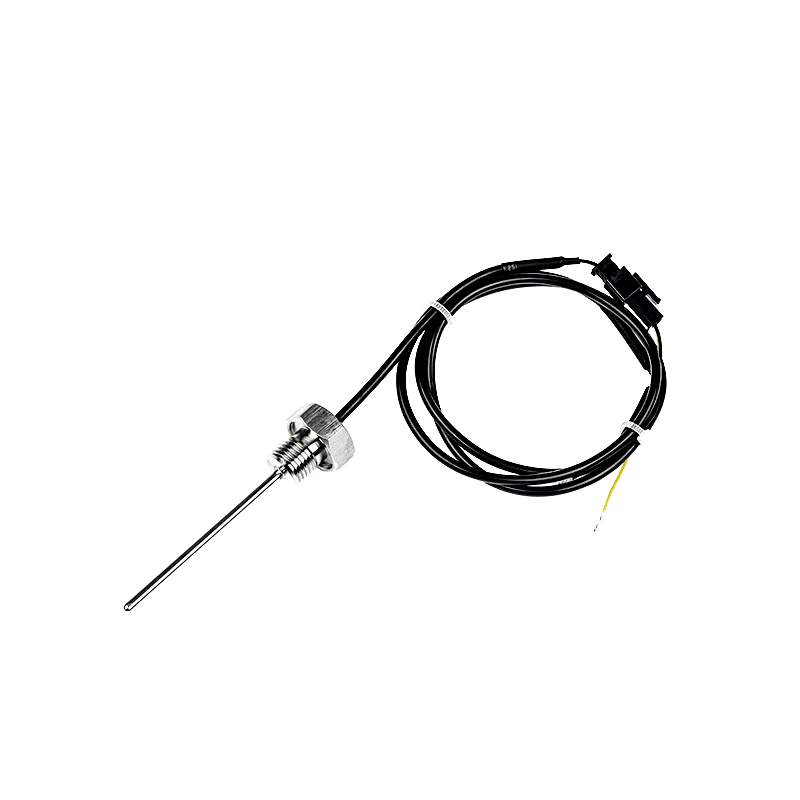

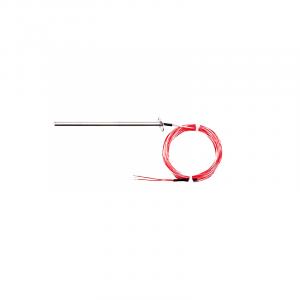

Food-grade SS304 tube, size, and appearance can be customized according to requirements. The product has excellent characteristic stability and consistency, high-temperature measuring accuracy, wide temperature measurement range, good moisture resistance, and high reliability.

The Features of Industrial Equipment Platinum Resistance Temperature Detector

| PT100, PT500, PT1000 Chip is Recommended | |

| Accuracy | 1/3B class, A class, B class |

| Working Temperature range | -60℃~+230℃, can be customized |

| Insulation Voltage | 1800VAC, 2sec |

| Insulation Resistance | 500VDC ≥100MΩ |

| Characteristics Curve | TCR=3850ppm/K |

| Long-term stability:the change rate is less than 0.04% when working 1000 hours at maximum temperature | |

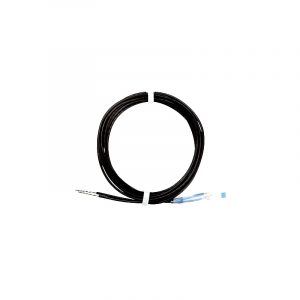

| Silicone cable or silver-plated wire with teflon sheath is recommended | |

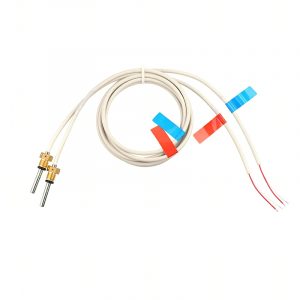

| Communication mode: two-wire system, three-wire system, four-wire system | |

| Product is compatible with RoHS and REACH certifications | |

| SS304 tube is compatible with FDA and LFGB certifications

The Applications of Platinum Resistance Temperature Detector Industrial temperature control, temperature testing box, electric power, medical treatment, instruments, meters |

|

The Working Principle of Platinum Resistance Temperature Detector

Similar to thermistors, platinum resistance temperature sensors (RTDs) are thermally sensitive resistors made of platinum. When calculating an RTD temperature by measuring a voltage, the DMM uses a known current source to measure the voltage produced by that current source. This voltage is the voltage drop across the two leads (Vlead) plus the voltage across the RTD (Vtemp). For example, a commonly used RTD has a resistance of 100Ω and produces only a change in resistance of 0.385Ω per 1°C. If each lead had a 10Ω resistance, it would cause a measurement error of 26°C, which is unacceptable. So a 4-wire ohm measurement should be done with the RTD.