Surface Mount Thermocouple: Enhancing Temperature Measurement Accuracy and Efficiency

Abstract:

Welcome to this comprehensive guide on surface mount thermocouples. In today’s fast-paced world, accurate temperature measurement is crucial in various industries. Whether you are a manufacturer, researcher, or simply interested in understanding the principles behind temperature monitoring, this article will provide you with valuable insights into surface mount thermocouples and their benefits.

Table of Contents:

1. Introduction

2. How Does a Surface Mount Thermocouple Work?

3. Advantages of Surface Mount Thermocouples

4. Applications in Various Industries

5. Factors to Consider When Choosing Surface Mount Thermocouples

6. Installation Guide for Surface Mount Thermocouples

7. Maintenance and Calibration Tips

8. FAQs about Surface Mount Thermocouples

9. Conclusion

1. Introduction

Temperature measurement plays a pivotal role in a wide range of industries, including electronics, automotive, aerospace, and food processing. To ensure accurate readings and efficient monitoring, professionals have turned to surface mount thermocouples. These miniature devices offer exceptional performance and are widely used in modern applications.

2. How Does a Surface Mount Thermocouple Work?

A surface mount thermocouple consists of two dissimilar metal wires, typically made of nickel-chromium and nickel-aluminum materials. These wires are welded together at one end, forming a hot junction. When exposed to heat or temperature fluctuations, a voltage is generated, which is proportional to the temperature difference between the hot junction and the other end, called the cold junction.

3. Advantages of Surface Mount Thermocouples

3.1 Miniature Design: The compact size of surface mount thermocouples allows for easy integration onto circuit boards and tight spaces, offering flexibility in various industrial applications.

3.2 Rapid Response Time: Surface mount thermocouples exhibit excellent response time, ensuring real-time temperature measurements and quick detection of any temperature changes.

3.3 High Accuracy: With advancements in technology, surface mount thermocouples provide high accuracy and repeatability, making them suitable for critical temperature monitoring in precision industries.

3.4 Cost-Effective Solution: Surface mount thermocouples are cost-effective compared to other types of temperature sensors, making them an ideal choice for budget-conscious projects.

4. Applications in Various Industries

Surface mount thermocouples find applications in diverse industries, such as:

4.1 Electronics: These thermocouples are widely used in electronic devices to monitor temperature variations during operation and prevent overheating, thus ensuring optimal performance.

4.2 Automotive: Surface mount thermocouples enable efficient monitoring of engine temperatures, contributing to improved engine performance, fuel efficiency, and overall safety on the road.

4.3 Aerospace: In the aerospace industry, surface mount thermocouples play a vital role in measuring temperatures in engine components, ensuring optimal functioning and safety during flights.

4.4 Food Processing: Surface mount thermocouples are employed in food processing environments to maintain accurate temperature control during cooking, cooling, and storing processes, ensuring food safety and quality.

5. Factors to Consider When Choosing Surface Mount Thermocouples

When selecting surface mount thermocouples for your specific application, several factors should be taken into consideration, including:

5.1 Temperature Range: Ensure the chosen thermocouple can operate within the required temperature range of your application.

5.2 Accuracy Requirements: Different applications may have distinct accuracy requirements. Select a thermocouple that meets your specific accuracy needs.

5.3 Response Time: Consider the response time needed for your application. Faster response times are crucial in applications where temperature changes occur rapidly.

5.4 Environmental Conditions: Evaluate the environmental conditions where the thermocouple will be installed, such as humidity, pressure, or chemical exposure, and choose accordingly.

6. Installation Guide for Surface Mount Thermocouples

Proper installation is essential to ensure optimal performance and accurate temperature measurements. Follow these steps for successful installation:

6.1 Prepare the Mounting Surface: Clean the mounting surface thoroughly, ensuring it is free from debris, contaminants, or any other substances that may affect the thermocouple’s performance.

6.2 Secure the Thermocouple: Use suitable adhesive or soldering techniques to firmly attach the thermocouple to the desired location, ensuring proper contact with the surface.

6.3 Cold Junction Compensation: To compensate for temperature variations at the cold junction, connect the thermocouple’s reference end to a cold junction compensation device.

7. Maintenance and Calibration Tips

To maintain the accuracy and longevity of your surface mount thermocouples, consider the following maintenance and calibration tips:

7.1 Regular Inspection: Periodically inspect the thermocouple for any signs of damage, wear, or deterioration and replace if necessary.

7.2 Calibration: Calibrate the thermocouples periodically using a reliable calibration equipment or service to ensure accurate temperature readings.

7.3 Cleaning: Clean the thermocouple regularly using appropriate cleaning agents and techniques, as recommended by the manufacturer.

8. FAQs about Surface Mount Thermocouples

8.1 Are surface mount thermocouples suitable for high-temperature applications?

8.2 Can surface mount thermocouples be used in corrosive environments?

8.3 How often should surface mount thermocouples be calibrated?

8.4 Can surface mount thermocouples be reinstalled after removal?

For answers to these frequently asked questions and more, refer to our comprehensive FAQ section on surface mount thermocouples.

9. Conclusion

Surface mount thermocouples offer accurate temperature measurement, rapid response time, and a compact design, making them an ideal choice for a wide range of applications. From electronics to automotive and aerospace industries, these miniature devices provide reliable temperature monitoring solutions. By considering factors such as temperature range, accuracy, and response time, you can select the most suitable surface mount thermocouple for your specific needs. Remember to follow proper installation guidelines, conduct regular maintenance, and calibrate as required to ensure optimal performance and accurate temperature readings throughout their lifespan.

Choose surface mount thermocouples for enhanced temperature measurement accuracy and efficiency in your industry!

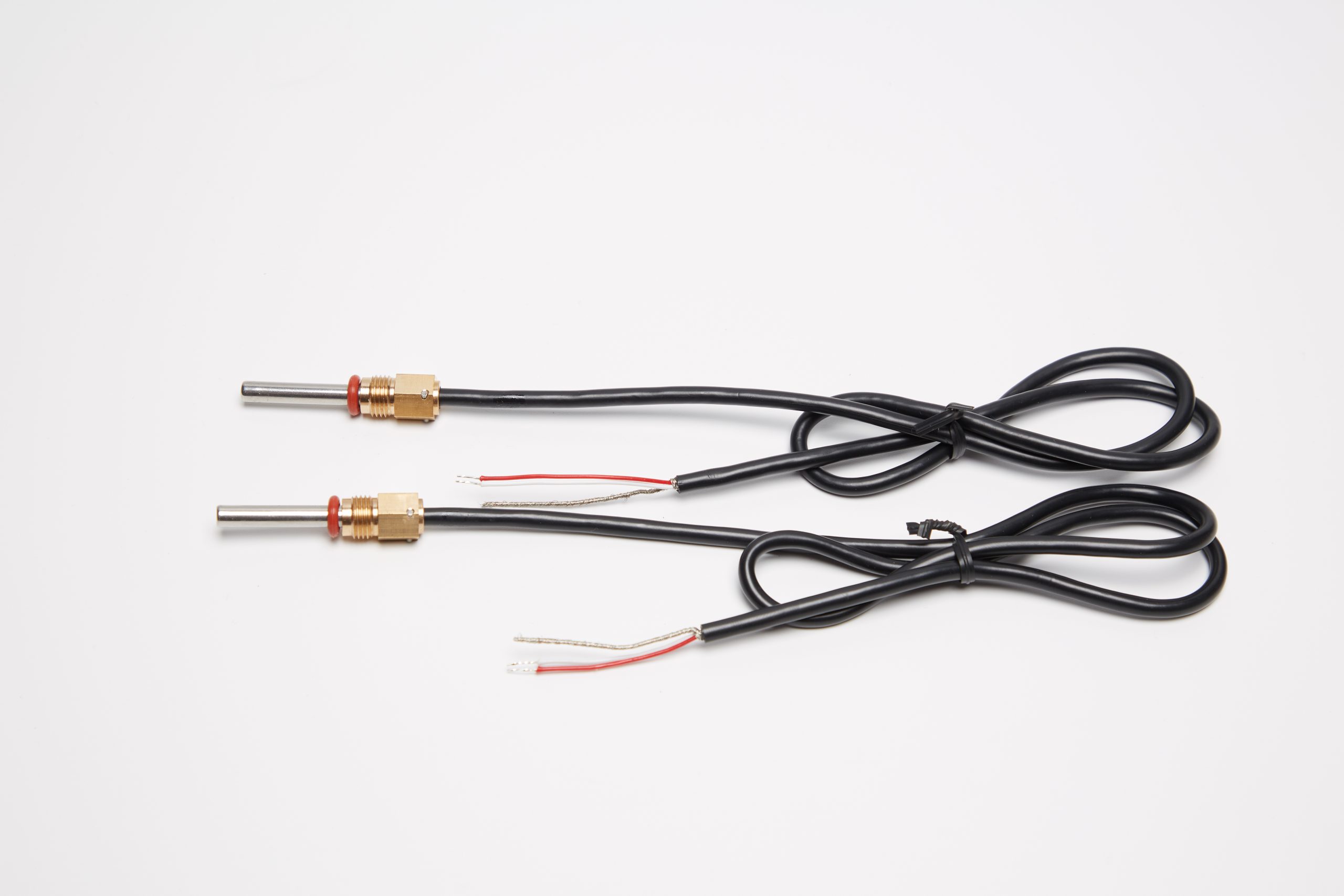

What Makes PT Sensors Manufacturer Solutions Stand Out in Heat Meter Applications

Introduction: PT sensors for heat meters offer ±0.1°C accuracy, customizable designs, automated quality control, and compliance with CJ 128-2007 and EN 1434 standards for reliable thermal measurement. In a