Temperature Transmitter 4-20mA: The Key to Accurate Temperature Measurement

Article Summary

- Introduction

- Importance of Temperature Transmitters

- How Temperature Transmitters Work

- Benefits of Using 4-20mA Temperature Transmitters

- Installation and Considerations

- Conclusion

Introduction

When it comes to temperature measurement in industrial applications, accuracy is paramount. One of the most crucial components in ensuring precise temperature readings is a temperature transmitter. In this article, we will explore the significance of temperature transmitters and focus specifically on the widely used 4-20mA temperature transmitter.

Importance of Temperature Transmitters

Temperature transmitters act as a bridge between the temperature sensor and the control system, converting the sensor’s analog output into a standardized signal that can be easily interpreted by devices such as PLCs and DCSs. By providing a reliable and consistent signal, temperature transmitters enable accurate temperature measurements, ensuring optimal process control and equipment safety.

How Temperature Transmitters Work

The 4-20mA temperature transmitter operates based on the principle of current loop technology. It utilizes a 4-20mA current signal to represent the temperature range being measured. At 4mA, the transmitter corresponds to the lowest temperature in the range, while at 20mA, it represents the highest temperature.

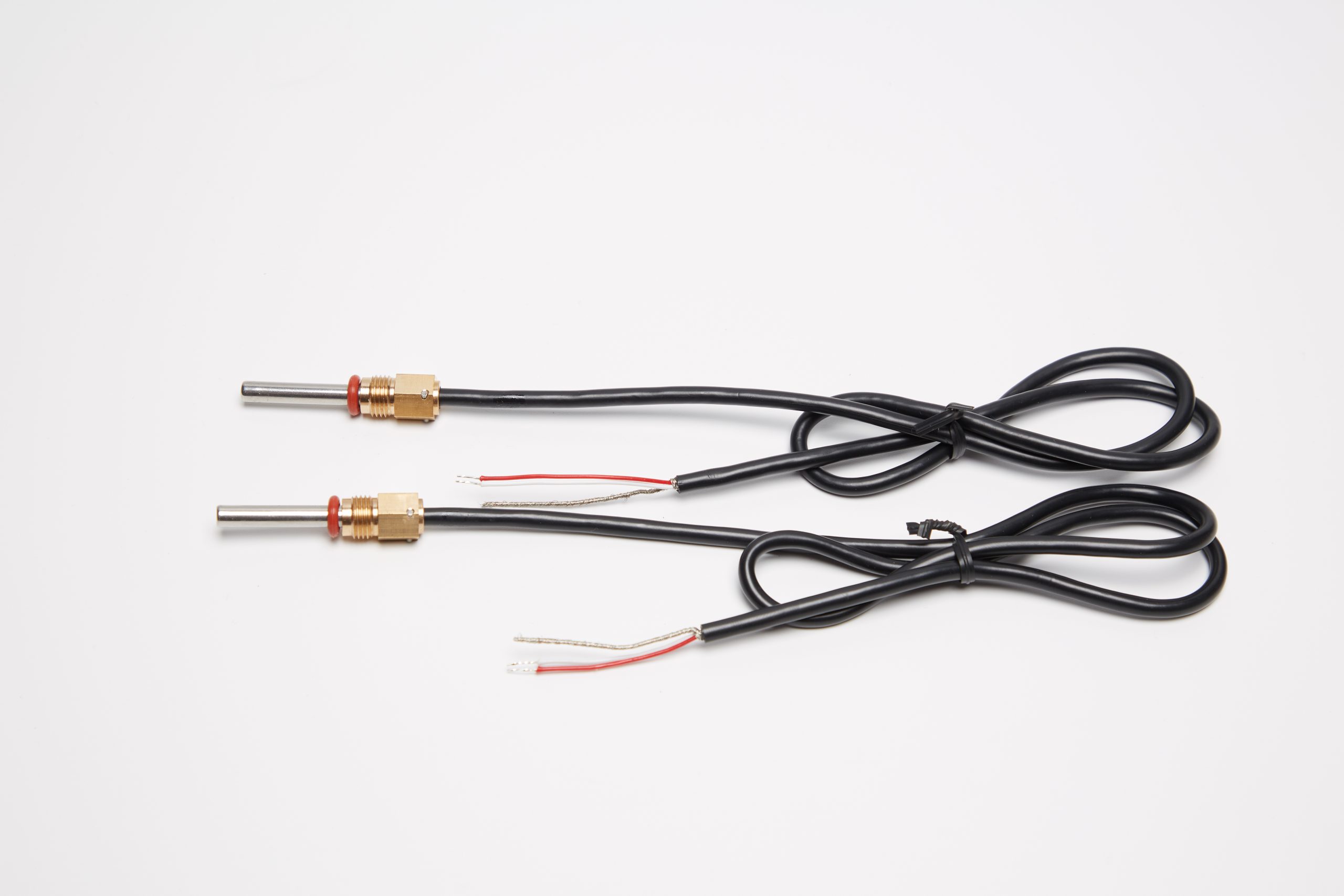

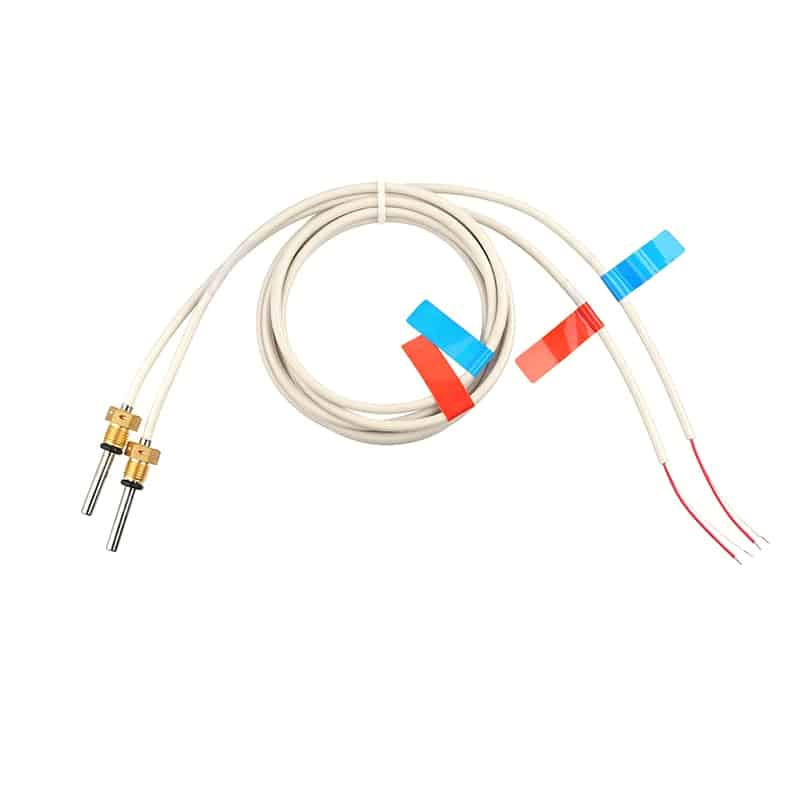

Inside the transmitter, a sensing element, such as a thermocouple or resistance temperature detector (RTD), detects temperature changes and generates a corresponding electrical signal. This signal is then converted into a 4-20mA current output, providing a linear relationship between the current and temperature.

Benefits of Using 4-20mA Temperature Transmitters

- Excellent noise immunity: The 4-20mA signal is less susceptible to interference, ensuring accurate readings even in noisy industrial environments.

- Long-distance transmission: The current loop technology allows temperature measurements to be transmitted over long distances without significant signal degradation.

- Easy integration: 4-20mA temperature transmitters are widely supported in industrial control systems, making them compatible with various devices and ensuring seamless integration.

- Fault detection: By monitoring the current loop, faults such as sensor failure or wiring issues can be detected, enabling prompt maintenance and preventing potential safety hazards.

- Flexible power options: The 4-20mA loop can be powered by a separate power supply, allowing for isolation between the control system and the measurement circuit, enhancing safety and reliability.

Installation and Considerations

When installing a 4-20mA temperature transmitter, several factors need to be considered. Proper sensor selection, wiring practices, and calibration procedures are crucial for accurate and reliable temperature measurements. Additionally, understanding the environmental conditions, such as ambient temperature and potential hazards, is essential to ensure the longevity of the transmitter and the safety of the system.

Conclusion

The use of temperature transmitters, particularly the 4-20mA variant, is fundamental in achieving precise temperature measurements in industrial settings. By providing a standardized signal and offering various benefits such as noise immunity and long-distance transmission, 4-20mA temperature transmitters contribute to optimal process control and enhanced equipment safety. Proper installation and consideration of environmental factors are key to maximizing the performance and longevity of these transmitters. Incorporating 4-20mA temperature transmitters into your temperature measurement systems will undoubtedly ensure accuracy, reliability, and efficiency.