In the quest for energy efficiency and accurate thermal measurement, heat meters have become an essential tool for both residential and commercial properties. At the heart of these sophisticated devices lies a crucial component: the temperature sensor. This article explores the indispensable role and functions of temperature sensors, particularly the PT1000 temperature sensor, in heat meters.

Understanding Heat Meters

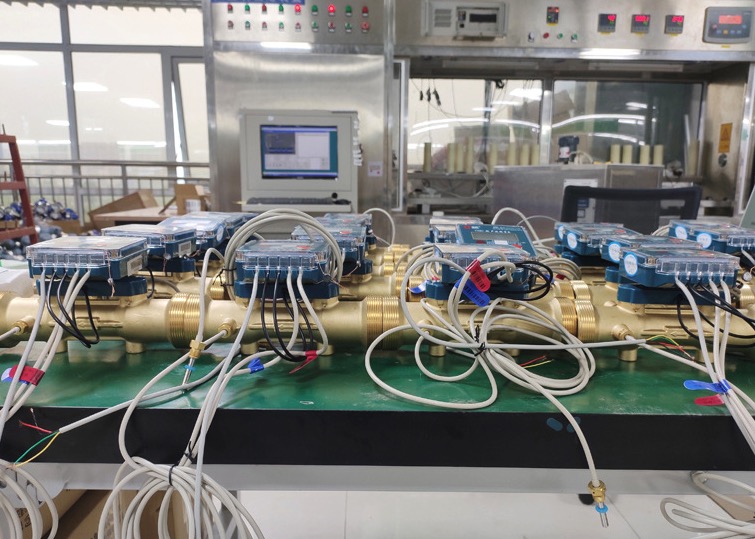

Heat meters, also known as energy meters or thermal meters, are devices used to measure the amount of thermal energy exchanged in a heating or cooling system. They are commonly employed in district heating systems, industrial processes, and residential heating systems to monitor and bill energy usage. A typical heat meter consists of three main components:

- Flow Sensor: Measures the volume of the heating or cooling fluid.

- Temperature Sensors: Measure the temperature of the fluid at different points.

- Calculator Unit: Computes the energy consumption based on the flow rate and temperature difference.

The Crucial Role of Temperature Sensors

Temperature sensors are integral to the accurate functioning of heat meters. They measure the temperature of the fluid entering and leaving the system, providing critical data for calculating the amount of energy transferred. Here are some key functions of temperature sensors in heat meters:

-

- Accurate Temperature Measurement: The primary function of temperature sensors is to provide precise temperature readings. The PT1000 temperature sensor, known for its high accuracy and stability, is often used in heat meters. These sensors can accurately measure temperatures over a wide range, ensuring reliable data for energy calculations.

- Energy Calculation: The energy consumption in a heating or cooling system is calculated based on the temperature difference between the incoming and outgoing fluid. Accurate temperature sensors are essential for this calculation, as even minor deviations can lead to significant errors in energy measurement and billing.

- System Efficiency Monitoring: By providing real-time temperature data, temperature sensors help in monitoring the efficiency of the heating or cooling system. They enable the detection of any anomalies or inefficiencies, allowing for timely maintenance and adjustments to optimize system performance.

- Compliance and Standards: Temperature sensors in heat meters must comply with international standards and regulations. The PT1000 temperature sensor meets these stringent requirements, ensuring that heat meters provide reliable and standardized measurements.

Advantages of PT1000 Sensors in Heat Meters

PT1000 sensors offer several advantages that make them an ideal choice for use in heat meters:

- High Accuracy: PT1000 sensors have a resistance of 1000 ohms at 0°C, providing high precision and consistency in temperature measurement.

- Wide Temperature Range: These sensors can operate over a broad temperature range, making them suitable for various heating and cooling applications.

- Long-term Stability: PT1000 sensors maintain their accuracy over extended periods, ensuring reliable performance and reducing the need for frequent recalibration.

- Durability: With robust construction, PT1000 sensors can withstand harsh environmental conditions, enhancing the durability and longevity of heat meters.

Types of Heat Meters

There are various types of heat meters available, including ultrasonic heat meters and mechanical heat meters. Ultrasonic heat meters use sound waves to measure the flow of the heating or cooling fluid, providing high accuracy and reliability. These meters are commonly used in both residential and industrial applications due to their precision and durability.

Installation and Maintenance

Proper heat meter installation is crucial for ensuring accurate energy measurement. Heat meters should be installed according to manufacturer guidelines and industry standards. Regular calibration and maintenance of temperature sensors, including the PT1000 temperature sensor, are essential to maintain the accuracy and reliability of the heat meter.

Conclusion

Temperature sensors, especially the PT1000 temperature sensor, play a pivotal role in the effective operation of heat meters. They ensure accurate temperature measurement, facilitate precise energy calculations, and contribute to the overall efficiency and reliability of heating and cooling systems. As the demand for energy efficiency and accurate billing continues to grow, the importance of high-quality temperature sensors in heat meters cannot be overstated. Investing in reliable sensors like the PT1000 is essential for achieving optimal performance and customer satisfaction in thermal energy measurement.