Thermocouple Sensor Types: A Comprehensive Guide to Understanding and Choosing the Right Option

Abstract:

This article provides a comprehensive guide to understanding the different types of thermocouple sensors available in the market. From exploring the principles behind thermocouple sensors to discussing their various applications, this guide aims to help you make an informed decision when choosing the right thermocouple sensor type for your specific needs.

Table of Contents:

1. Introduction

2. Understanding Thermocouple Sensors

3. Popular Thermocouple Sensor Types

3.1 Type K Thermocouples

3.2 Type J Thermocouples

3.3 Type T Thermocouples

3.4 Type E Thermocouples

3.5 Type N Thermocouples

4. Factors to Consider When Selecting a Thermocouple Sensor Type

4.1 Temperature Range

4.2 Accuracy and Sensitivity

4.3 Durability and Resistance to Environmental Factors

4.4 Cost

5. Applications of Thermocouple Sensors

5.1 Industrial Applications

5.2 HVAC Systems

5.3 Automotive Industry

5.4 Food Industry

6. Installation and Maintenance Tips

7. Conclusion

1. Introduction

Thermocouple sensors play a crucial role in temperature measurement and control across various industries. With their wide temperature range, fast response times, and durability, thermocouple sensors are popular choices for many applications. In this guide, we will explore the different types of thermocouple sensors available in the market, the factors to consider when selecting the right type, and their applications in different industries.

2. Understanding Thermocouple Sensors

Thermocouples work based on the principle of the Seebeck effect, where a voltage is generated when two dissimilar metals are joined at two different temperatures. This voltage is directly proportional to the temperature difference between the measurement junction (hot junction) and the reference junction (cold junction). By measuring this voltage, the temperature can be determined.

3. Popular Thermocouple Sensor Types

3.1 Type K Thermocouples

Type K thermocouples are one of the most commonly used thermocouple types. They offer a wide temperature range (-200°C to +1372°C) and high accuracy. Type K thermocouples are suitable for various applications, including industrial processes, laboratories, and heat treatment facilities.

3.2 Type J Thermocouples

Type J thermocouples are suitable for lower temperature applications, ranging from -210°C to +1200°C. They are popular in the food industry, as they can withstand the corrosive effects of certain food substances.

3.3 Type T Thermocouples

Type T thermocouples have a temperature range of -200°C to +400°C. They exhibit high accuracy and stability, making them ideal for cryogenic applications and scientific research.

3.4 Type E Thermocouples

Type E thermocouples have a temperature range of -270°C to +1000°C. They are known for their high accuracy and resistance to oxidation, making them suitable for applications in the automotive industry and research laboratories.

3.5 Type N Thermocouples

Type N thermocouples have a temperature range of -200°C to +1300°C. They offer high stability and accuracy, especially at higher temperatures. Type N thermocouples are commonly used in the aerospace industry and research laboratories.

4. Factors to Consider When Selecting a Thermocouple Sensor Type

4.1 Temperature Range

Consider the temperature range of your application and select a thermocouple sensor type that can operate within that range without compromising accuracy or durability.

4.2 Accuracy and Sensitivity

Different thermocouple sensor types have varying degrees of accuracy and sensitivity. Consider the level of precision required for your application and choose a thermocouple sensor type accordingly.

4.3 Durability and Resistance to Environmental Factors

Certain environments may expose thermocouple sensors to corrosive substances or extreme conditions. Evaluate the durability and resistance to factors like moisture, chemicals, and vibration when selecting a thermocouple sensor type.

4.4 Cost

Thermocouple sensor prices vary depending on the type and brand. Consider your budget and the cost-effectiveness of the sensor type for your specific application.

5. Applications of Thermocouple Sensors

5.1 Industrial Applications

Thermocouple sensors find extensive use in industrial settings, including manufacturing processes, power generation, and chemical plants. They enable precise temperature control and help maintain operational efficiency and product quality.

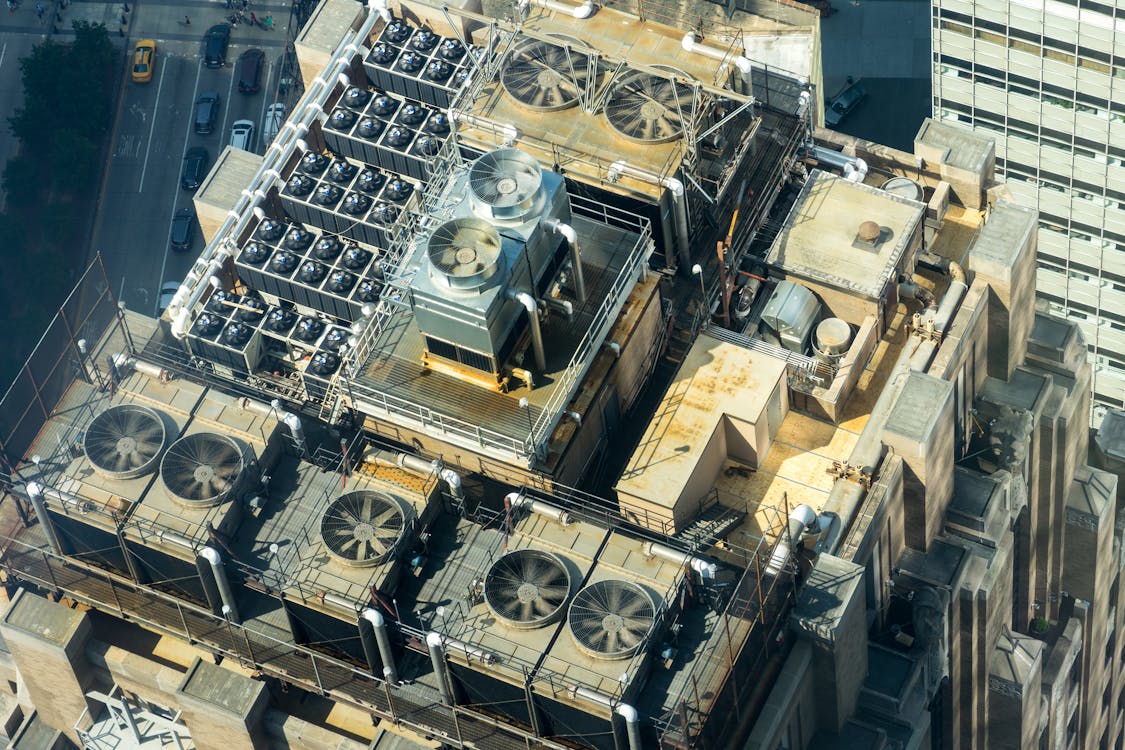

5.2 HVAC Systems

Thermocouple sensors are essential components in heating, ventilation, and air conditioning (HVAC) systems. They ensure accurate temperature monitoring and regulation, contributing to optimal energy usage and occupant comfort.

5.3 Automotive Industry

Thermocouple sensors play a critical role in automotive applications, such as engine performance monitoring, exhaust gas temperature measurement, and emission control. They aid in optimizing fuel efficiency and complying with environmental regulations.

5.4 Food Industry

The food industry relies on thermocouple sensors for temperature monitoring during food processing, storage, and transportation. They help maintain food safety and quality by ensuring proper temperature control.

6. Installation and Maintenance Tips

Proper installation and regular maintenance are crucial for optimal performance and longevity of thermocouple sensors. Follow manufacturer guidelines for installation procedures and perform routine checks for any signs of wear, damage, or calibration drift.

7. Conclusion

Selecting the right thermocouple sensor type is essential for accurate temperature measurement and control. By understanding the different options available, considering factors such as temperature range, accuracy, durability, and cost, and assessing their applications in various industries, you can make an informed decision. Remember to follow proper installation and maintenance practices to maximize the performance and lifespan of your thermocouple sensor.

Why Custom Temperature Sensors Are the Future of Precision Monitoring 🌡️⚙️

In today’s rapidly evolving industrial landscape, precision temperature monitoring is more important than ever. Off-the-shelf sensors often fail to meet the unique demands of specialized applications, leading to inefficiencies, inaccuracies,