In today’s rapidly evolving industrial landscape, precision temperature monitoring is more important than ever. Off-the-shelf sensors often fail to meet the unique demands of specialized applications, leading to inefficiencies, inaccuracies, and reduced equipment lifespan. This is where custom temperature sensors come into play — offering tailor-made solutions that elevate performance, reliability, and even competitive advantage.

The Limitations of Standard Temperature Sensors

Standard sensors are designed for general-purpose use, but industrial environments are rarely standard. From extreme heat and vibration to corrosive atmospheres and compact installation spaces, specialized applications require more than a one-size-fits-all approach.

Why Custom Temperature Sensors Matter?

Custom temperature sensors solve these challenges by providing:

✅ Tailored Calibration Custom sensors can be calibrated specifically to the operational range of your application, ensuring optimal linearity, repeatability, and minimal measurement drift.

✅ Enhanced Durability Built using application-specific materials, they are more resistant to oxidation, corrosion, or mechanical stress — extending sensor life and reducing downtime.

✅ Optimized Response Time Custom probe geometry and housing designs allow for faster thermal response, enabling real-time monitoring and better system control.

✅ Extended Temperature Range From cryogenic systems to furnaces above 1600°C, custom sensors are built to handle extreme environments that standard sensors cannot.

✅ Improved Signal Stability Specialized cables and shielding options reduce EMI (electromagnetic interference), ensuring stable and reliable data — especially in industrial automation and energy sectors.

Custom Sensors Enhance Product Uniqueness and Market Advantage

Beyond performance, custom temperature sensors offer a strategic edge for manufacturers:

🔒 Difficult to Replicate – A custom-designed sensor becomes a proprietary component of your product. Competitors can’t easily copy it without access to your design and calibration data.

💰 Hard to Price Match – Unique specifications make it difficult for buyers to benchmark or compare pricing with standard products, protecting your margins.

🛠 Brand Identity – A sensor designed for your system enhances both functionality and differentiation, setting your product apart in the market.

At Starlight, we support this competitive edge with in-house mold development and tooling capabilities. Whether it’s a unique probe head, overmolded connector, or specialized mounting interface — we can custom-develop both the function and the form of the sensor for your exact needs.

Real-World Applications of Custom Sensors

📌 Steel Manufacturing Custom thermocouples with ceramic sheaths allow precise monitoring in blast furnaces, where temperatures exceed 1500°C. These sensors withstand extreme thermal cycling and ensure process control.

📌 Chemical Processing PT100 sensors with Teflon or Inconel coatings are used to monitor aggressive chemical environments, ensuring both sensor longevity and process safety.

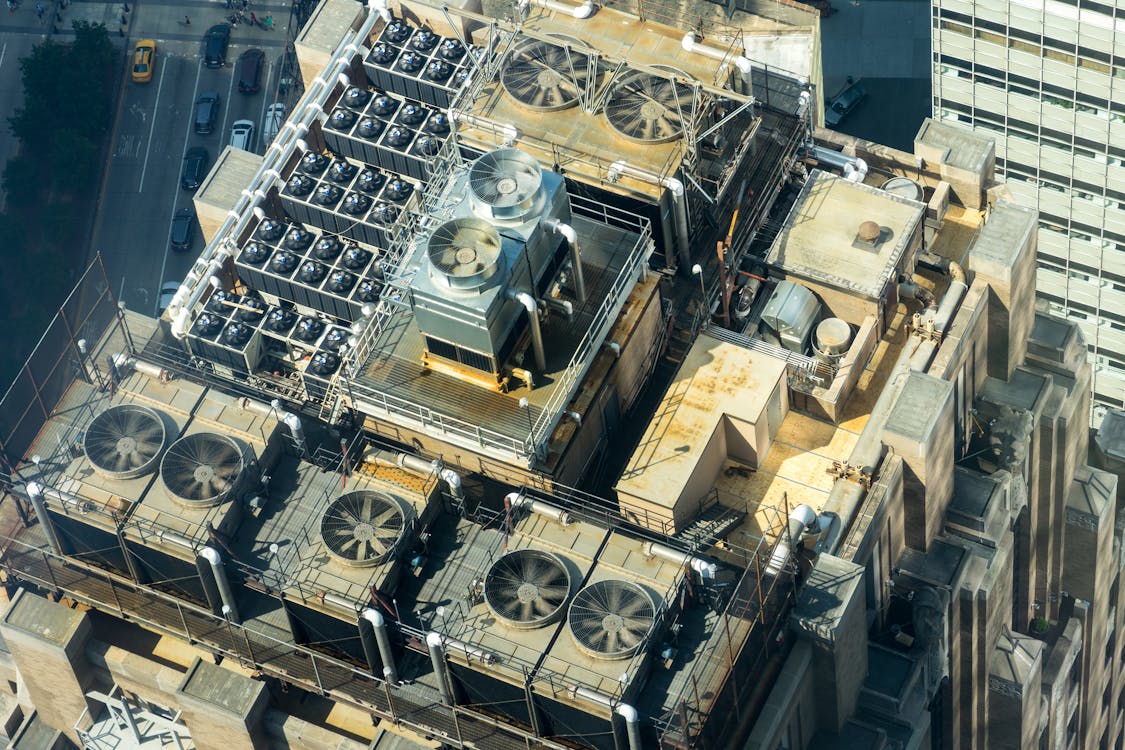

📌 HVAC and Refrigeration TPE overmolded NTC sensors are tailored for cold environments — such as refrigerators, freezers, and cold storage warehouses — offering fast response and moisture resistance.

📌 Smart Appliances and IoT Miniature, waterproof sensors designed to integrate seamlessly with smart controllers, supporting the growing demand for connected temperature control systems.

Emerging Technologies Driving the Future of Custom Sensors

The future of sensor innovation is already here — and it’s being shaped by customization:

🔗 Wireless Integration Custom sensors are being integrated with Bluetooth, LoRa, or Wi-Fi modules, enabling real-time remote monitoring and seamless IIoT deployment.

🧠 AI-Driven Predictive Maintenance Sensor data feeds into machine learning systems that detect anomalies and predict failures before they happen, reducing downtime.

🔧 Self-Calibrating Systems Next-gen sensors now include built-in diagnostics and auto-calibration features, reducing the need for manual intervention.

Why Choose Starlight as Your Custom Sensor Partner

At Starlight, we specialize in the design and manufacturing of custom thermocouples, RTDs, and NTC/PTC sensors for a wide range of industries — including automotive, home appliances, energy systems, HVAC, and automation.

What sets us apart:

- ✅ Full in-house R&D, tooling, and molding capabilities

- ✅ ISO-certified quality management

- ✅ Fast prototyping and sample support

- ✅ Global customer base and export experience

- ✅ Professional OEM/ODM customization service

Whether you need a K-type thermocouple for industrial use, a high-accuracy PT100 for process control, or a waterproof NTC sensor for smart appliances, we build sensor solutions tailored to your exact needs.

Conclusion

The demand for custom temperature sensors is growing rapidly — not just for performance reasons, but also for strategic product differentiation. Companies that invest in custom sensors benefit from higher accuracy, better durability, and stronger market positioning.

As a trusted manufacturer, Starlight is committed to helping you engineer smarter, more competitive products with sensor solutions built to last.